Table of Contents |

When a facility has high energy needs, safety becomes an utmost concern. An air circuit breaker (ACB) effectively protects facilities and employees from increased electricity flow. ACBs also ensure that electrical systems are running efficiently and correctly.

Below, we’ll cover the basics of ACBs and how they work. We’ll also look at some of the different types of ACBs and their applications.

How Does Air Circuit Breaker (ACB) Work?

Circuit breakers are designed to stop the flow of electricity under certain conditions, usually during situations like an overcurrent or short circuit or to direct the flow of the system. A circuit breaker is made up of contacts that will separate when a problem occurs. Stopping the flow of electricity keeps conditions safe and prevents damage to equipment.

Air circuit breakers operate using pressurized air. As the breaker trips, the contacts will separate, creating an arc. ACBs eliminate the arc, keeping the current steady and safe. ACBs are an alternative to oil circuit breakers, which are not as safe. It’s also important not to confuse ACBs with vacuum circuit breakers, which extinguish the arc using a vacuum. A VCB is the better choice for indoor, high-voltage use, while an ACB is better for industrial settings.

In an ACB, when the contacts separate – due to overcurrent, short circuit or for operating purposes – the ACB works to eliminate the arc, making the equipment safer. The ACB uses a combination of air pressure and conductive elements to guide the arc away from the circuit safely and then stretches it until it is eliminated.

What are the Main Components of ACB?

Several components work together in an ACB. One of the main features is a blast valve. When the arcing contacts separate and the arc forms, the blast valve opens arc chutes. Pressurized air pushes through the arc, disconnecting it from the contacts.

The pressurized air pushes the arc towards arcing probes and rings. These are conductive elements that help to move the arc away from the contacts. As the arcing contacts get farther apart, the arcing probes and coils get closer together, allowing them to attract the arc.

The arc is moved into the chutes toward an arcing electrode. Eventually, the arc is pushed through the chutes and stretched until it is completely eliminated.

Types of ACB

There are four main types of ACBs. Below, we’ll discuss each type, its functions and its use cases.

Plain Brake Type ACB

Plain brake-type ACBs are the most basic design. The arc contacts are shaped like horns. When the circuit breaks and the contacts move apart, the arc forms between them. The plain brake type then uses air pressure to elongate the arc until it extinguishes.

These are often used in low-voltage situations with up to 12,000 volts. Plain brake types ACBs work with DC and AC currents.

Magnetic Blowout Type ACB

A magnetic blowout type ACB uses a magnetic field to aid in eliminating the arc. The magnetic field does not extinguish the arc. When the arc is formed, blowout coils create a magnetic field. The magnetic field helps to move the arc along the chutes, where the pressurized air elongates it and eventually eliminates it.

Magnetic blowout-type ACBs are used in equipment with voltages below 11,000 volts.

Air Chute ACB

Air chute ACBs employ two types of contacts – primary contacts made of copper and arcing contacts made of silver. During a break, the primary contacts separate before the arcing contacts, protecting the primary contacts from the arc. The arc contacts also close before the primary contacts for protection.

Air chute ACBs are used in high-voltage situations, with voltages reaching 420 KV or more.

Air Blast Circuit Breaker

An air blast circuit breaker uses pressurized air to move and extinguish the arc. When the break creates the arc, a valve opens, allowing pressurized air to move up through an arc chute. The air guides the arc up where it elongates and is extinguished.

Air blast circuit breakers are used in medium-to-high voltage situations, with voltages of up to 15 KV.

Applications of Air Circuit Breakers

If you have heavy equipment with high energy needs, an ACB is a worthwhile investment. Most equipment is costly to repair or replace, so an ACB can prevent many issues that may arise. ACBs protect your equipment in the event of energy malfunction.

It’s important to test an ACB to ensure it works properly regularly. The testing procedure involves first checking the ACB inside and out to make sure that all equipment is in good order. You may need to clean or lubricate some areas.

Next, you’ll perform mechanical and electrical operation tests to ensure proper functioning. You’ll perform injections on electronic trip components. This process will calibrate the breaker to certain points.

If you’re not comfortable working with electric equipment, you can always hire a professional to test the ACB. They can safely and effectively check that your ACB is working.

Conclusion

An ACB is a wise choice when it comes to protecting your equipment and facility, along with keeping all of your electrical needs running smoothly. ACBs are safer and easier to maintain than oil circuit breakers.

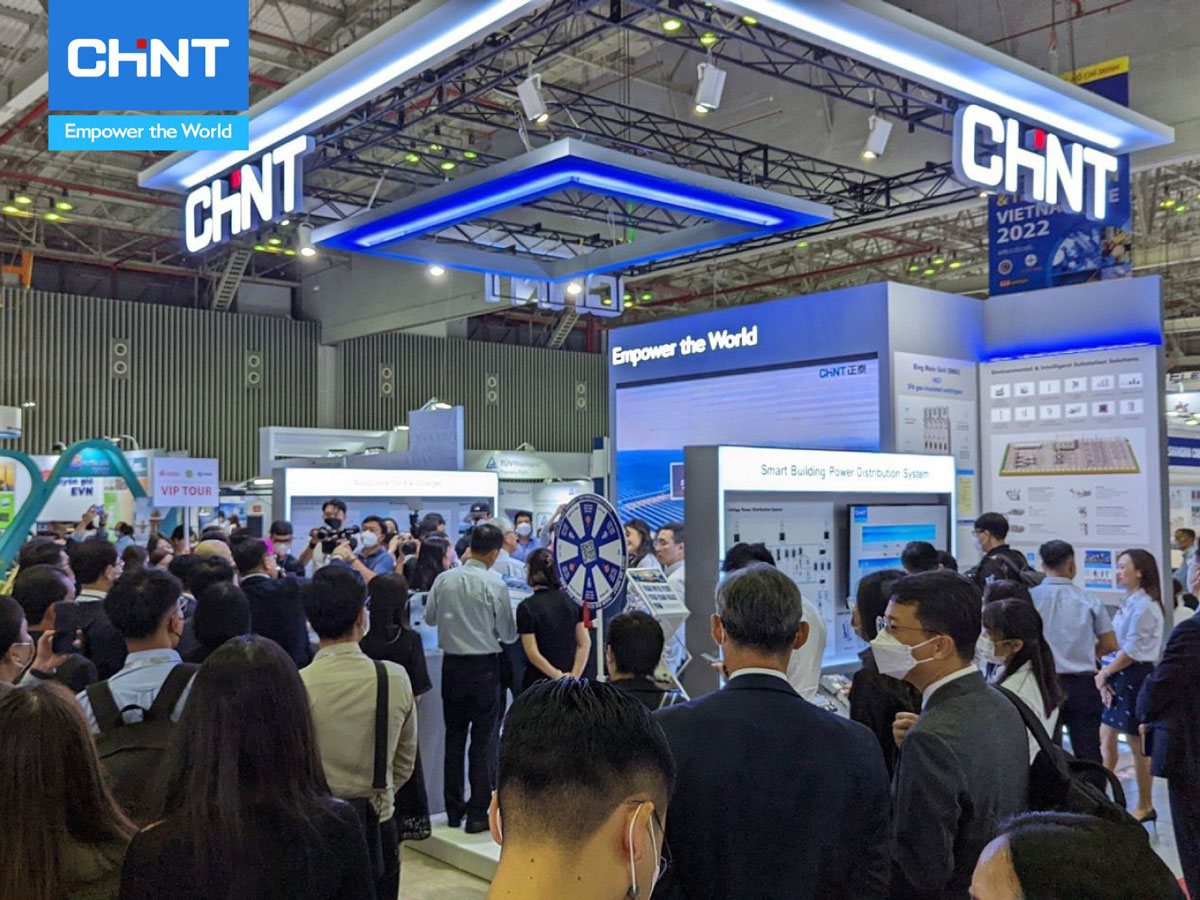

CHINT air circuit breakers are efficient and durable. Contact us today to determine which of our ACBs is the best option for your situation.

FAQ about Air Circuit Breakers

What is an air blast circuit breaker ACB usually used for?

If you have any questions or need further assistance, don't hesitate to reach out to us.

-metalclad-AC-enclosed-switchgear-banner.png)