Introduction

Molded case circuit breakers protect circuits from faults, overcurrents, and shorts. An MCCB’s frame size can affect how you build your electrical panel to handle high current loads and comply with standards. If you’re looking for a high-capacity MCCB, CHINT is a global supplier that offers products such as their M6 MCCB, which is excellent for high-capacity applications.

What Is an MCCB and Frame Size?

A molded case circuit breaker is a mechanism that protects circuits from faults, overcurrents, and short circuits. MMCCBs are encased in insulating materials and house trip devices, current-carrying units, and mechanisms. They are primarily used in low-voltage distribution panels.

An MCCB frame size refers to the size of the switching mechanism found inside. The frame size of an MCCB determines how much current it can handle. This capacity is separate from a trip unit’s current rating. However, the frame size can serve as an indicator of the trip unit sizes that can be used.

In industrial settings, 800-1200A are standard frame sizes. This preference is due to a larger frame size, which means higher current capacity, reduced likelihood of overheating, and a wider range of trip unit compatibility.

Why Frame Size Matters in Industrial Loads

When applied and used in an industrial setting, it is common to see molded case circuit breakers with bigger frame sizes. This is because higher frame sizes have a higher current-carrying capacity, better protection from overheating, can handle more mechanical load, and exhibit better compliance.

When used in high-current industrial circuits, general electric molded case circuit breakers should have thermal and mechanical stability. Due to the high electrical and mechanical loads, fuses and circuit breakers with low capacities are overwhelmed and will not function properly. Using an MCCB with the correct frame size enables better heat dispersion, resulting in continuous performance and the ability to handle more mechanical load.

When working on an industrial-class circuit, it is crucial to comply with international safety standards established by regulations and laws. Compliance with safety standards protects your operation and employees.

MCCBs used in industrial applications also require high flexibility in terms of trip settings and accessories. A great example is the CHINT M6, which has adjustable trip units, shunt trip, and UVT. Adjustable trip units allow operators to determine the parameters for currents and short circuits. Having a built-in shunt trip allows you to trip a circuit breaker remotely, and UVTs protect your circuit from sudden power drops.

All in all, having the correct frame size for an MCCB is crucial, as it enables your operation to remain functional and comply with industry safety standards.

Factors to Consider When Choosing MCCB Frame Sizes

When selecting an MCCB for your power distribution system, consider several factors before making a decision. Making the wrong choice can lead to non-compliance with safety standards and put your workers and operation at risk.

Current And Voltage Ratings

When selecting your circuit breakers, be aware of the demands on your operation’s power distribution system. Select a circuit breaker that has the correct ratings so that it adheres to your electrical system’s load. Selecting the proper circuit breaker also enables you to comply with industrial voltage standards.

System Fault Current Capacity

Always select an MCCB with a frame size that has a breaking capacity that exceeds your maximum prospective fault current. This allows your system to continue operating seamlessly, even in the event of a sudden surge or fault. Exceeding the maximum prospective fault current will also help your electrical system to be future-proof.

Application Environment

Your MCCB should be capable of working with high industrial heat, dust, space constraints, and vibration.

- If the protective frame is not heatproof enough, it can lead to overheating, which ultimately results in faults.

- Excessive dust can affect the performance, as it can also lead to overheating.

- Excessive vibrations can cause internal components to misalign, leading to a decline in performance.

- Lastly, space constraints can affect your layout, as other vital mechanisms may not fit within your panel.

Coordination with Other Protection Devices

When selecting a frame size, ensure that it can accommodate selective coordination with fuses and downstream breakers. This will allow maximum protection for your system as the component closest to the fault will be the only one to trip.

Future Scalability

If you’re considering expansion, opt for an MCCB with a larger frame size. This will allow your MCCB to accommodate the projected increase in electrical load.

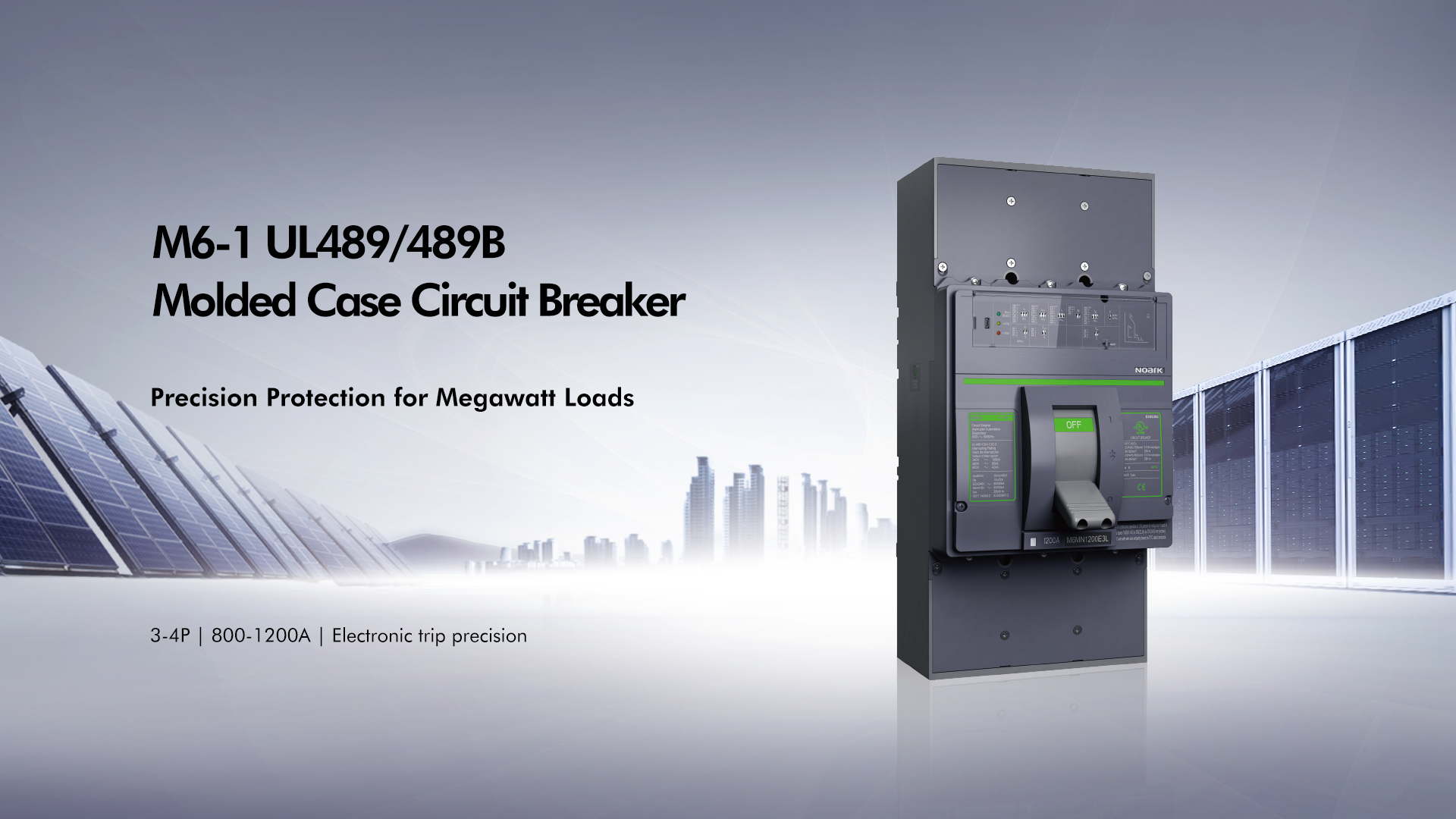

CHINT M6 MCCB in Large-Scale Power Distribution

If you’re looking for a reliable industry-grade MCCB, look no further than the CHINT M6 Frame Size 800~1200A MCCB. This circuit breaker complies with international industry standards, meeting UL 489, CSA, and IEC/EN 60947-2 requirements. The M6 also features a high-breaking capacity, which allows you to break high fault currents from short circuits with urgency. The arc-extinguishing design will help protect your circuit as well as your operators.

The CHINT M6 also features adjustable trip settings that will allow you to modify parameters for potential breaks. This will enable your electrical system to operate with higher capacity, ensuring maximum performance and safety. The M6 is also compatible with a wide array of accessories for control and monitoring, allowing you to use components that can maximize your circuit.

The CHINT M6’s features make it the perfect MCCB for industrial operations such as manufacturing plants, data centers, and utility facilities. The M6 protects wide-scale electrical systems by addressing faults with urgency while being flexible enough to adjust to your operations’ needs.

Selection Process for Industrial Applications

Follow these tips to ensure your electrical systems are safe from faults.

- Assess load requirements and fault levels. It is best to assess your load requirements and fault levels before installing an MCCB. It will help you determine the frame size required for your electrical systems. This will also help in future-proofing your system in case of expansion.

- Determine compliance and safety standards. Knowing which compliance and safety standards to follow will help in selecting an MCCB unit. Units that comply with regulations and standards will help protect your electrical systems and workers.

- Select a frame size that meets both operational and future needs. When selecting a frame size, consider the needs of your current operation. It is also a good practice to anticipate and prepare for future operational needs in case of expansion.

- Consider integration with existing panel space and accessories. Make sure that the frame size you select integrates well with your panel space and accessories. Having sufficient space allows for better installation, and maximum compatibility ensures a seamless update. For example, if you want to purchase the M6, you can consult with CHINT’s engineers to better match your components with their MCCBs.

Conclusion

Selecting the correct MCCB frame size for industrial circuit breakers will allow you to protect your electrical systems. CHINT is a company that aims to deliver reliable solutions, as showcased by their M6 MCCB. For more information, you can visit our website for specifications or schedule a consultation with an expert.

/molded-case-circuit-breaker-(mccb)-(ul)/molded-case-circuit-breaker-(mccb)/m6-frame-size-800~1200a(mccb)/product-image/M6 Frame Size 800~1200A Frame Size 800~1200A(MCCB).png.thumb.319.319.png)

-metalclad-AC-enclosed-switchgear-banner.png)