Table of Contents |

Molded Case Circuit Breakers (MCCB) is a required component of electrical systems, providing overload protection and short-circuit protection. In most cases, MCCBs are installed in the main power distribution board of a facility, allowing the system to be easily shut down when necessary. MCCBs are available in various sizes and ratings, depending on the size of the electrical system.

In this guide, we’ll cover the components and features of a typical MCCB, how they work, and which types are available. We’ll also discuss the benefits of using this type of breaker in your electrical system.

What is a Molded Case Circuit Breaker

A molded case circuit breaker, or MCCB, is a safety device used to protect an electrical circuit from overload or short circuits. It works by automatically cutting off the power supply when a fault or overcurrent situation arises, thus preventing any damage to the electrical system. MCCBs can be used in both low-voltage and high-voltage systems.

In addition to providing protection against faults, they also provide isolation of the circuit for maintenance. MCCBs are typically installed in the distribution panel and provide a visible indication to let users know when the power is off.

The main components of an MCCB are:

Molding Case

The molded case or frame is the cushion that keeps all parts of the circuit breaker in place. It is solidly built from ‘glass polyester’ or ‘thermoset composite resin that gives a great nonconducting strength despite its compressed size.

Terminals

The terminals serve as connectors between external conductors and molded cases. They should be connected properly to prevent unusual heat production.

Operating Apparatus

This is the switch that opens and closes the molded case. Its handle connects the pull of the device and manual push.

Trip 'Unit

The Trip System is composed of temperature and current-reactive electromagnetic sensors that trigger the Operating Apparatus in case of short-circuit or current overloads. Its button can be pressed to reset the circuit breaker.

Arc Chamber

The Arc Extinguisher’s primary role is to curb and split the arc that can damage your circuit breaker. The action results in exterminating the current flow in the circuit breaker. Inside the arc chamber are contacts. Their role is to conduct and disrupt functions. Arc ‘Runners, on the other hand, function as new electrodes for the arc. Arc chutes, on the other hand, compress the arc in the middle of sidewall insulators.

Molded Case Circuit Breaker Application

On application, MCCBs are designed to handle high currents, especially on expensive equipment. You will often find MCCB used commonly used in industrial-levels of machinery such as the following:

Motors

MCCBs protect motors by having their settings modify the inrush current and give the delay it may need. When done correctly, the motors are protected from overloads without triggering the tripping mechanism.

Welding Machinery

Welding machines utilize high currents, which normal circuit breakers cannot handle. An MCCB can be used to protect welding machines by connecting the machine to its own circuit breaker.

Generators

It is widely known that generators produce high levels of amps and need costly gen-sets. To shield the linked circuits and generator from faults that may happen in the system, having an MCCB is essential as it can handle its high current ratings and protects your generators as needed.

Capacitor Banks

MCCB lessens the currents, which in turn, corrects the ‘power factor’ in commercial and industrial-level systems.

Modifiable Trip Modes

These settings allow MCCBs to be utilized in low-current appliances in the household. This makes it an all-rounder use as it can be adjusted between low and high-current settings.

Electric Feeders

MCCB has adjustable settings that can be adjusted and allows it to handle high currents. If applied to electric feeders that produce hundreds of amps, MCCB can dissipate these energies easily. It also acts as its primary ‘incoming breaker.

Molded Case Circuit Breaker Ratings

Molded case circuit breakers (MCCBs) have a variety of ratings that determine their performance and suitability for different applications. Some of the main molded case circuit breaker ratings include:

- Rated Current (In) is the exceeding value when the overload protection reaches its tipping point. You can modify these values in MCCB.

- Rated Frame Current (Inm) is the maximum capacity value of the MCCB and dictates its ‘physical form.

- Rated Insulation Voltage (Ui) is the maximum current MCCBs can handle as evidenced by the conducted tests. It is greater than the rated working voltage to give an allocated safety margin while in use.

- Rated working voltage (Ue) is the uninterrupted operating voltage of MCCB. This is usually equal to or near the standard level of system voltage.

- Operating short-circuit breaking capacity (Ics) is the maximum ‘fault current that MCCB can ‘trip without permanent damage. You can continue using the MCCB after a fault interruption, provided it doesn’t go beyond the limits.

- Mechanical life is the number of times you can operate the device manually before it dysfunctions.

- Electrical life is the estimated number of times the MCCB can ‘trip before it completely becomes unusable.

Molded Case Circuit Breaker Vs Traditional Circuit Breaker

Traditional Circuit Breakers can operate under 100 amps with an interrupting rating of below 18,000 amps. They don’t have tripping sensors to detect exceeding currents. They cannot be modified as they are designed to accommodate low circuits. It is also utilized for domestic use, like small appliances and home wiring.

On the other hand, MCCBs can be modified with their trip settings for higher models. They can produce amps ranging from 10-2,500, and the interrupting rating is estimated between 10,000-200,000 amps. This allows them to be adjusted to handle between low and high currents.

With their higher capacity, it is no surprise that they can be used in motors, welding machines, and factories, as it only takes a remote control to trip and turn them on or off. They are also used in commercial or industrial use as standby power.

Normally, they are reset after being tripped. One has to look into manufacturers before settling on one to ensure that one can rely on high-quality and long-lasting MCCBs.

Conclusion

MCCBs are a must-have in any industrial, commercial, or home wiring. They are designed to be adjustable and can handle low and high currents. Their trip settings enable them to be used in applications such as motors and welding machines, while their higher capacity allows them to handle large electrical feeders. In any case, it is important to consult with the manufacturers to get reliable and high-quality MCCBs.

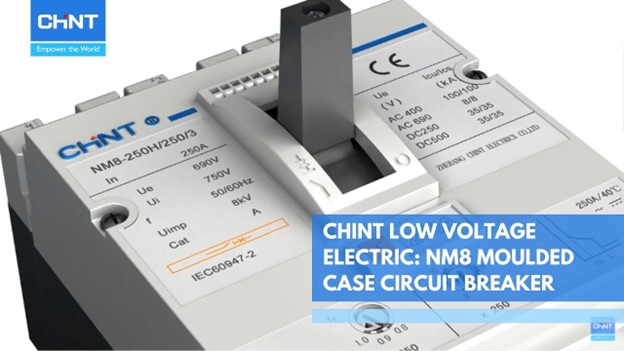

At Chint Global, we provide quality MCCBs certified by international safety standards. We offer a full range of molded case circuit breakers to suit different applications, from low-current to high-current settings. Contact us to find out more about our products and services.

If you have any questions or need further assistance, don't hesitate to reach out to us.

-metalclad-AC-enclosed-switchgear-banner.png)