Introduction

Behind every byte and transaction lies more than servers; it's the data center power system engineered for stability. Even milliseconds of interruption can compromise data integrity, making resilient data center electrical design critical.

Strong, intelligent power infrastructure ensures continuity, uptime, and the reliability modern digital operations demand.

How Stable Power Architecture Impacts Data Center Operations

Every modern data center runs on more than servers, as it now runs on carefully orchestrated electricity. Even a momentary power outage can cascade into downtime, lost transactions, or compromised data.

That’s why data center electrical design should be a strategic consideration, especially in Tier III and IV facilities, where uptime is non-negotiable.

Here’s how a stable power architecture shapes operations:

- Ensures uptime and redundancy: Multiple feed paths, parallel transformers, and backup UPS systems allow continuous operation even if one component fails.

- Manages fault risks: Short circuits, overloads, or equipment failures are isolated quickly through switchgear and breakers, protecting downstream systems.

- Smooths load transitions: Server racks, cooling systems, and network equipment often draw fluctuating power. A robust backbone accommodates spikes and dips without tripping.

- Layered infrastructure: Power flows from the utility through MV/LV transformation, to switchgear, UPS, distribution panels, and finally into rack-level delivery, creating clear control points and monitoring layers.

- Stability in operations: Predictable power paths make maintenance, load balancing, and expansion safer and easier, reducing the risk of unscheduled downtime.

Data centers are highly reliable, operationally continuous, and can be easily scaled by considering power as a strategic resource and not an incidental factor.

The backbone not only feeds servers, but it also safeguards business-critical workloads, protects sensitive equipment, and ensures that digital services stay online without interruption.

Solid Power Distribution Path for Modern Data Centers

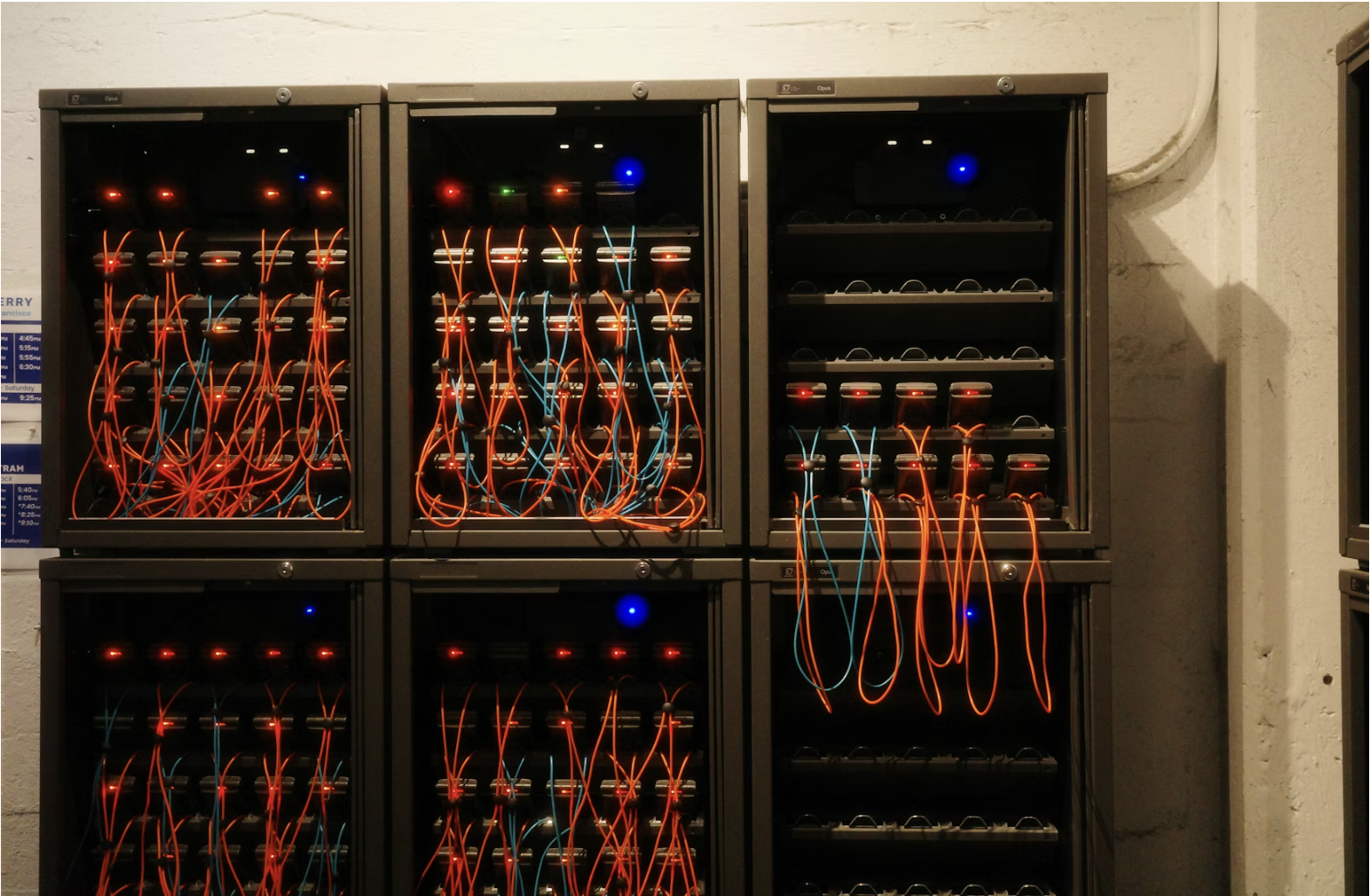

A modern data center’s reliability begins with a clearly defined power path. Electricity enters from the utility or on-site generation and passes through medium- or low-voltage transformers into LV switchgear, which serves as the first layer of protection and control.

From there, power moves into UPS systems that stabilize voltage and provide short-term backup during interruptions. Downstream distribution switchboards then feed busways or PDUs, which finally deliver electricity to rack-level PDUs powering individual IT equipment. This layered approach makes sure each component is monitored, protected, and coordinated to maintain continuous service.

Furthermore, this architecture is based upon redundancy. Popular models often follow N, N+1, or N+2 designs, where extra capacity allows maintenance or component failure without affecting operations.

Proper selective coordination between breakers, fuses, and protective relays prevents unnecessary shutdowns of healthy circuits while isolating faults.

Safety and equipment protection are highly essential. Short-circuit protection, arc-flash mitigation, and protective device coordination ensure faults don’t escalate into destructive events. LV switchgear and UPS systems are carefully specified to meet these criteria, creating a stable, resilient backbone.

An efficient and well-organized power distribution for data centers allows operators to gain predictable performance, safer environments, and the ability to scale infrastructure without compromising uptime.

Electrical systems become as dependable as the digital workloads they support.

Modular Switchgear as the Foundation of Maintainable Operations

Data centers should incorporate electrical systems that are flexible, scalable, and able to adapt seamlessly to the ever-evolving operational needs. Given these requirements, modular switchgear has become the preferred architecture for many specialists.

Operators can roll out power infrastructure faster, expand capacity without major rewiring. They also perform maintenance safely while the rest of the facility remains online, as they break the system into standardized, self-contained units.

Such systems are especially valuable when scaling a Tier III or IV data center. As load grows or new server clusters come online, modules can be added or reconfigured while keeping upstream and downstream circuits operational.

This predictable behavior supports fault isolation and ensures that a single failure does not cascade across the facility.

CHINT EnergiX-P40 switchgear exemplifies the principles of an advanced data center electrical design. Its architecture supports modularity, live-swappable outgoing circuits, and a compact busbar system. Compliance with IEC 61439-2 ensures standardized safety, while multiple outgoing lines accommodate varied IT rack configurations.

Features like these help data center operators implement structured, maintainable power distribution paths, allowing energy to be routed efficiently, monitored reliably, and adjusted quickly in response to changing loads.

Reliable operators meet stringent uptime requirements, maintain adaptability, and boost security by taking full advantage of modular switchgear. It becomes more than hardware, as it’s a key recipe for maintainable, resilient, and predictable data center operations.

Intelligent Distribution at the Rack Zone for Better Management and Uptime

Power at the rack level is a point of control, insight, and protection for the entire data center. PDUs, RPPs, and integrated metering systems give operators visibility into every circuit, helping maintain load balance and ensuring that no single rack or device is overloaded.

Without this insight, even small imbalances can blow up, triggering trips, reducing uptime, or stressing sensitive IT equipment.

Intelligent PDUs take this a step further. By providing real-time monitoring, they track voltage, current, and power quality, enabling early detection of potential faults before they disrupt operations.

They also support trending and analysis, so operators can anticipate load growth, plan capacity upgrades, and make informed energy-management decisions. This level of insight is crucial for reporting compliance, sustainability goals, and maintaining Tier III/IV uptime standards.

CHINT’s Low-Voltage Main Power Distribution offerings include components like:

- Air Circuit Breakers (ACBs)

- Molded Case Circuit Breakers (MCCBs)

- Transfer Switches (TSEs)

- Surge Protection Devices (SPDs)

These are all designed for safe, reliable, and flexible power delivery. At the rack zone, the EnergiX-P40 Power Distribution Cabinet exemplifies modern CHINT PDU design: modular, high-reliability, and capable of supporting multiple outgoing circuits.

Integrated branch-circuit monitoring allows operators to see real-time load conditions for each rack, ensuring balanced distribution and early warning for anomalies.

When these tools are all combined, data centers gain stable power and, at the same time, actionable intelligence.

Operators can optimize capacity planning, improve energy efficiency, enforce compliance reporting, and maintain uptime, all while reducing risk to IT equipment and supporting scalable growth.

Intelligent rack-level distribution is significantly important in advanced, resilient data center operations.

The Intelligence Layer Behind Data Center Power

It is the intelligence behind the electrical system that transforms the raw energy in a way that can be predicted, controlled, and be future-proof. Without continuous insight, even a well-engineered infrastructure can become difficult to maintain or scale.

Full Visibility Into Electrical Behavior

Modern facilities need incessant awareness of load profiles, shifting demand patterns, harmonics, voltage irregularities, as well as power factor trends. These details shape everything from cooling capacity to breaker coordination.

When operators can see how the system behaves in real time, they can correct issues early on instead of reacting after something fails.

Integration With BMS and DCIM Platforms

Intelligent monitoring tools don’t work in isolation; they feed information straight to BMS or DCIM systems. It creates a unified operational picture, including environmental conditions, energy consumption, alarms, and event logs, which are connected altogether.

Issues can be more easily tracked, and teams waste less time in speculation on the cause of problems.

Predictive Maintenance and Planning

With fast, accurate data coming from meters and sensors, operators gain the ability to forecast capacity needs, schedule maintenance before equipment degrades, and prevent incidents caused by overloads or poor power quality.

The intelligence layer transforms the act of monitoring into proactive decision-making, which enables data centers to remain dependable as they grow.

CHINT provides data-driven visibility through IEC/UL/CE-compliant metering solutions. The DDSU666 single-phase smart meter offers precise energy measurement, multi-parameter monitoring, Modbus-RTU communication, DIN-rail mounting, bi-directional kW/kWh measurement, and an active-power refresh rate of ≤50 ms.

For DC systems, the iDCM7 DC smart meter measures voltage up to 1000 V and current up to 650 A, with RS485 or Ethernet communication, high accuracy, low consumption, a large LCD display, and simple installation.

Both tools support predictive maintenance, early anomaly detection, and trend analysis.

CHINT’s operations follow its global Integrity and Compliance Code, ensuring consistent standards across its presence in more than 140 countries, including long-standing experience supporting telecom sites and data centers.

Conclusion

Reliable data center operations start with a power architecture built for stability, visibility, and seamless continuity. When every layer, from upstream distribution to rack-level intelligence, is designed with care, uptime becomes far easier to protect.

CHINT, as a global provider of electrical and intelligent distribution technologies, supports the scalable, dependable infrastructure modernized data centers rely on to stay running.

.jpeg)