Introduction

A consistent power supply is vital to the operation of critical facilities like hospitals, laboratories, and manufacturing plants. Hence, in the event of a power outage, a backup source is a must.

A diesel generator is one of the most common and reliable backup power solutions for continuous operation. This device converts chemical energy stored in diesel to electrical energy through an engine and an AC alternator. Some even feature control panels, radiators, and fuel tanks.

In this blog, we discuss how to safely use a diesel generator to keep critical commercial and industrial operations running.

Core Safety Devices in Industrial Diesel Generators

To enhance the safety and reliability of industrial diesel generators, various core safety devices can be used in conjunction with them.

Air Circuit Breakers (ACBs)

ACBs interrupt electric arc and flow using the dielectric and cooling properties of air. They are typically installed in facilities that operate with high current and high voltage applications.

Air circuit breaker is an example of a commercial and industrial ACB with a voltage capacity of up to around 635Vac and 3200 amps. You may use this ACB as the main fuse system or breaker for industrial diesel generators to prevent hazards during an electric fault.

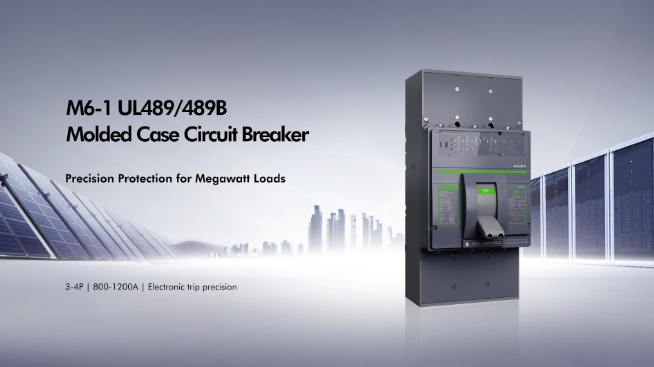

Molded Case Circuit Breakers (MCCBs)

An MCCB is a medium-voltage circuit breaker that protects an electric circuit from a short circuit or overload. This device uses bimetallic strips that trip the MCCB to interrupt current flow during a short circuit. Meanwhile, it generates a strong electromagnetic field to open MCCB’s contacts and cut power in case of an overload.

This device can “track” the power generated by a diesel backup generator and cut current flow instantly in case of an electric fault.

CHINT offers various MCCB frame sizes that work reliably with industrial diesel generators. For instance, the CHINT M series MCCB provides a range of rated interrupting voltages from 240 to 690 Vac and 250 to 600 Vdc, for ultimate circuit, equipment, and facility protection in case of an electric fault.

Miniature Circuit Breakers (MCBs)

MCBs are compact, automatic electrical switches designed to protect low-voltage electrical circuits from damage caused by overcurrent conditions, including short circuits and overloads. In diesel generator applications, MCBs serve as essential protection devices for individual circuits and loads.

For industrial diesel generators, MCBs are commonly installed in distribution panels to protect individual branch circuits, control circuits, and auxiliary equipment.

Contactors

Contactors are electrically controlled switches designed to handle high current loads in industrial diesel generator systems. These devices provide remote control capability for starting, stopping, and switching generator loads, making them essential for automated operation and load management.

In generator applications, contactors are used for automatic transfer switching, load shedding, and emergency disconnection. Modern contactors often include auxiliary contacts for status indication and control circuit integration.

Push Botton

Push buttons are manual input devices that allow operators to interact with and control diesel generator systems. These devices provide essential human-machine interface capabilities for system operation, emergency control, and maintenance procedures.

Industrial push buttons are designed to withstand harsh environments and frequent operation. They include various types such as start/stop buttons, emergency stop buttons, selector switches, and indicator push buttons. Emergency stop buttons feature distinctive red mushroom-head design and positive opening action to ensure reliable emergency shutdown.

Push buttons in generator systems are typically arranged in control panels with clear labeling and logical grouping. They provide immediate manual override capabilities and are essential for maintenance, testing, and emergency response procedures. Modern control buttons often include LED illumination for status indication.

Indicator Lights

Indicator lights provide visual status information about the operating condition of diesel generator systems and their associated safety devices. These devices offer immediate visual feedback to operators and maintenance personnel about system status, alarms, and operational parameters.

Industrial indicator lights use LED technology for long life, low power consumption, and high visibility.

In diesel generator applications, indicator lights display critical information such as generator running status, mains availability, fault conditions, fuel levels, temperature warnings, and safety system status. They are typically mounted on control panels, remote monitoring stations, and at key locations throughout the facility for maximum visibility and quick status assessment.

Disconnectors

A safety relay can switch the state of the control circuit without faults according to command signals, ensuring the flawless operation of the entire machine.

Disconnectors (also called isolation switches) separate the diesel generator set from the electrical system physically. This device ensures safety when technicians are working with the system as it provides a quick and reliable way to cut off power.

Diesel Generator vs Other Backup Systems: Safety Comparison

Most industrial and commercial facilities use traditional energy sources like gas generators and battery ESS as backup. So, why do many acquire a generator from diesel generator suppliers?

Safety is the most compelling reason. In this section, we compare it to the two aforementioned typical generators.

System Type |

Safety Considerations |

Industrial Sustainability |

Diesel Generator

|

|

Suitable for high-volume industrial operations and most reliable for long-duration backup and challenging conditions. |

Gas Generator |

|

Recommended for medium- to large-scale use, but requires strict monitoring for gas leaks and reliable fuel infrastructure. |

Battery Energy Storage System (ESS) |

|

Best for short-duration backup scenarios and facilities that are striving for cleaner energy generation.

|

The comparison above indicates that diesel generators are the most robust and capable for high-volume and high-voltage facilities. Their engines withstand heavy loads and operate for extended periods without loss of performance. And with advanced protection systems, such as molded case circuit breakers and air circuit breakers, you can ensure safe operation even under severe and sudden electrical stress.

The effectiveness of industrial diesel generator safety systems depends not only on individual device quality but also on how these components work together as an integrated protection network. CHINT, as a globally renowned leader in smart energy solutions, provides extensive support and resources to ensure seamless integration with existing systems.

System-Level Protection Architecture

CHINT's Low-voltage Main Power Distribution products ensure safety and reliability with advanced protection, smart monitoring, and global compliance. The integration strategy follows a hierarchical protection approach:

Primary Protection Layer: ACBs and MCCBs provide the first level of protection against major faults, handling high-current interruption and protecting the main generator circuits.

Secondary Protection Layer: MCBs protect individual branch circuits and loads, providing selective protection that isolates only affected circuits during minor faults.

Control Layer:Contactors provide remote switching capability. Control buttons allow manual intervention, and indicator lights provide immediate visual feedback.

Intelligent System Integration

CHINT's Intelligent Solutions offer enhanced safety, reliability, and efficiency for electrical systems, enabling real-time monitoring, predictive maintenance, and intelligent control.

- Centralized alarm management and fault diagnosis

- Remote control capabilities for non-critical operations

- Historical data logging for maintenance planning

- Integration with fire safety and emergency shutdown systems

Modular Safety Solutions

CHINT designs its safety device portfolio with modularity in mind, allowing customers to start with basic protection and expand their systems as needs grow. The modular approach includes:

Basic Safety Package: Essential protection with ACBs/MCCBs, basic contactors, and manual controls Enhanced Safety Package: Addition of safety relays, intelligent monitoring, and automated controls Complete Safety System: Full integration with building systems, remote monitoring, and predictive maintenance capabilities

Selecting the Right Safety Devices for Your Generator System

Choosing the appropriate CHINT safety devices for diesel generator applications requires careful consideration of multiple factors including power requirements, application environment, safety standards, and future expansion needs.

Power and Current Rating Considerations

The foundation of proper safety device selection lies in accurate power analysis. Chint circuit breakers offer superior safety and performance suitable for residential, commercial, or industrial applications with specific current and voltage ratings.

Generator Size Matching: For diesel generators ranging from 50kW to 2MW, CHINT offers corresponding safety devices:

- Small generators (50-250kW): MCCBs in 100-400A range with MCB distribution panels

- Medium generators (250kW-1MW): MCCBs in 400-800A range or ACBs up to 1600A

- Large generators (1-2MW+): ACBs from 1600-3200A with comprehensive protection systems

Load Characteristics: Different applications require specific safety considerations:

- Data Centers: Require high reliability with dual power paths and seamless transfer capabilities

- Hospitals: Need immediate backup power switching with fail-safe mechanisms

- Manufacturing: Focus on protecting sensitive equipment from power quality issues

- Commercial Buildings: Balance cost-effectiveness with adequate protection levels

Application-Specific Device Selection

Healthcare Facilities Healthcare applications demand the highest reliability standards. The recommended CHINT configuration includes:

- ACBs for main generator protection with hospital-grade specifications

- Emergency stop systems integrated with hospital fire and safety protocols

- Indicator systems providing clear status information for medical staff

Data Centers Data center applications require seamless power transitions and high availability:

- MCCBs with electronic trip units for precise protection coordination

- Contactors rated for frequent operation in automatic transfer systems

- Intelligent monitoring systems for predictive maintenance

Technical Specifications and Compliance

Technical specifications should prioritize current ratings, voltage compatibility, and ensure compliance with relevant standards. Key selection criteria include:

Voltage Ratings: CHINT devices accommodate various voltage systems:

- Low voltage applications: 230V-690V AC systems

- DC applications: 125V-600V DC for battery backup integration

- Control voltages: 24V DC, 110V AC, 220V AC for auxiliary systems

Environmental Considerations: Device selection must account for installation environment:

- Temperature ranges: Mostly (-25°C to +70°C) or extended range options

- Humidity and corrosion resistance for coastal or industrial environments

- Vibration resistance for engine room installations

- IP ratings appropriate for enclosure requirements

Cost-Benefit Analysis and Investment Planning

CHINT safety devices offer competitive total cost of ownership through:

Initial Cost Optimization:

- Standardized product lines reduce procurement complexity

- Volume pricing available for complete system packages

- Reduced engineering costs through proven integration solutions

Operational Benefits:

- Best in class cost leadership driven by value engineering and world class supply chain efficiency

- Reduced maintenance costs through reliable operation

- Lower insurance premiums due to enhanced safety systems

Future-Proofing Investment:

- Modular design allows for system expansion without complete replacement

- Smart device options provide upgrade paths to intelligent monitoring

- Standardized interfaces ensure long-term compatibility

Technical Support and Service Advantages

CHINT provides extensive support including technical consultation to help customers select the right solutions for their needs, as well as customized solutions to ensure seamless integration. This support includes:

- Pre-sales engineering consultation for optimal system design

- Custom configuration services for unique applications

- Training programs for installation and maintenance personnel

- Comprehensive documentation and technical resources

- Global service network for ongoing support and spare parts availability

The combination of proven technology, comprehensive product range, and strong technical support makes CHINT safety devices an optimal choice for industrial diesel generator applications, ensuring reliable operation and long-term value.

(1) IEC 60947: Stipulates requirements for low-voltage switchgear and controlgear, such as circuit breakers and protective relays. Refer here to determine the correct methodology for reliable isolation and fault protection in generator installations.

(2) NEC (National Electrical Code): Provides comprehensive guidelines for generator wiring, grounding, overcurrent protection, and integration with building electrical systems, to minimize fire and shock hazards.

When you acquire a generator safety device, like ACBs or MCCBs, source one from a manufacturer that complies with established standards. For instance, CHINT offers smart energy generation and safety solutions that adhere to IEC, NEC. This ensures maximum performance while guaranteeing the safety of the facility’s equipment and personnel.

Ensure Safe Operation of Industrial Diesel Generator With CHINT’s Safety Devices

Even the best-engineered diesel generator for sale needs safety devices, like circuit breakers and disconnectors, to ensure safe operation. These devices can detect electrical faults within milliseconds and interrupt current flow to reduce hazard risks and ensure operational continuity.

With over four decades of industry experience, CHINT is a leading provider of high-end and reliable energy solutions for industrial and commercial facilities. We offer leading-edge safety devices for diesel engine generators, such as ACBs, RCCBs, and MCCBs, for safe, energy-efficient, and cost-effective operation.

.jpeg)

.jpeg)

.png)

.png)

.png)