Table of Contents |

Precise control over the speed and torque of motors is of utmost importance. Over-speeding motors leave mechanical stress and wreck motor windings and bearings. Insufficient torque renders motors under stall conditions, which can lead to motor damage and even complete failure. Variable speed drives (VFD) can address these issues by controlling the frequency and voltage of AC delivered to electric motors. They are widely used in different scenarios. Two major applications of variable frequency drives are constant torque loads and variable torque loads.

How Variable Speed Drives Control Constant Torque Loads

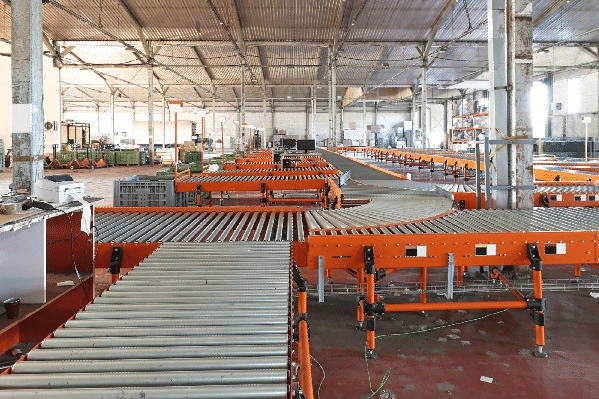

Constant torque loads refer to devices that require constant torque during operation. Typical constant torque loads include compressors, conveyors, hoists, mixers, rewinders, etc. The torque of the electric motors for these devices should remain the same at all motor speeds. For example, constant torque means the conveyors can move items at a steady pace at each speed mode. This is especially important for handling fragile items.

To achieve constant torque, variable frequency drives must be used to control the frequency and voltage of electric motors precisely. A variable speed drive should increase the voltage supplied to electric motors linearly as it increases frequency, and decrease the supplied voltage as the frequency decreases.

How Variable Speed Drives Control Variable Torque Loads

As the name suggests, the torque of variable torque loads changes during operation. Typical variable torque loads include centrifugal pumps, fans, blowers, etc. These applications only require low torque at low operating speeds and much higher torque at high speeds. The load torque required is approximately proportional to the square of the speed.

Variable speed drives precisely modulate the motor torque and speed in these variable torque applications. This precise control aligns the motor’s output with the exact load requirements, thereby enhancing energy conservation. To illustrate, if a fan’s speed reduces by half, the torque required reduces to a quarter. The horsepower, which equals speed times torque, consequently drops to one-eighth of its original value. This reduction in horsepower consumption translates into improved energy efficiency for the fan’s operation.

Product Highlight: CHINT NVF2G-S General Purpose VFD

With nearly four decades of industry experience, CHINT is a renowned manufacturer and supplier of variable speed drives. At CHINT, our VFDs are designed with advanced technology. CHINT NVF2G-S General Purpose VFD is an example of our commitment to innovation and performance. It can be applied to both constant torque and variable torque loads. Its main advantages include:

Adaptable to Different Application Scenarios

CHINT NVF2G-S General Purpose VFD excels in adaptability. It operates efficiently in temperatures ranging from -10°C to 55°C, with a derating requirement between 45°C and 55°C. This surpasses competitors like Schneider, which has a narrower temperature range of 0°C to 50°C. Additionally, the NVF2G-S accommodates an expanded input voltage of 380V to 440V and an output frequency of up to 400Hz, making it suitable for high-speed applications.

Parameter Replication

This adjustable speed drive allows parameter replication. This is particularly beneficial for OEM industries with standardized equipment, where identical parameters across multiple drives are the norm. Instead of individually configuring each unit, this feature allows for the configuration of one drive to be cloned onto others. It streamlines the setup process, saves time, and minimizes the risk of manual errors.

Torque Control Function

CHINT NVF2G-S General Purpose VFD features an advanced torque control function, which significantly impacts performance in precision applications. Imagine the challenge in toilet paper production, where too little tension results in loose rolls, and too much leads to tears. The frequency converter’s torque control addresses this by maintaining a steady force. This translates to consistently high product quality.

Conclusion

Overall, variable speed drives provide precise control over the torque and speed of electric motors. They are used for constant torque and variable torque loads. Suitable for both applications, CHINT NVF2G-S General Purpose VFD stands out for its high adaptability, parameter replication and torque control function. Browse our website to learn more about our variable speed drives.

-metalclad-AC-enclosed-switchgear-banner.png)