Table of Contents |

Solar PV manufacturing has been providing excellent advantages to manufacturing industries. It offers an effective solution to provide energy resources globally. Thus, the solar manufacturing sector is essential to adapt to the growing demand for solar energy.

It is the industry that covers with production and assembly of the materials used to build solar energy systems. The company under this industry is also known as a PV manufacturer.

What is a PV Manufacturer?

The solar energy system comprises various materials to make it work, mainly the solar PV panels or photovoltaic. These devices are used to convert sunlight and generate electricity through a natural process involving semiconductors.

These panels and other subcomponents of the system are made and assembled by a PV module manufacturer. It’s the one responsible for providing reliable products to power up simple electric gadgets to home appliances.

Why is Solar Manufacturing Important?

PV manufacturers are the contributors to keeping the supply chain of solar energy systems consistent. They provide substantial products for the growing demand for cost-effective electricity supply and support the economy of a country.

Furthermore, with enough PV module suppliers, it will help reduce the dependence of the country on foreign energy supply. As a result, this will support the economy’s growth and development.

The growing domestic solar manufacturing industry is a great help not just for the people but also to a particular department in the country, such as the Department of Energy. As the industry flourish, related U.S departments will also have the opportunity to collect data and research for further development.

PV Manufacturing Basics

PV module manufacturing provides a diverse operation process since the system requires various components other than the PV panel. It includes cells, frames, wafers, glass back sheets, and power electronic parts.

Thus, the fabrication covers various steps starting from polysilicon production, ingot and wafer production, cell fabrication up to module assembly. Here’s a rundown of the basics of PV manufacturing to familiarize you with solar energy system production.

Polysilicon Production

Most PV modules are made from silicone materials called Polysilicon which is the focus of the first step in the solar energy system operation. Polysilicon is a beaded shape silicone with high-purity composition.

The manufacturers process the polysilicon using the Siemens method breaking the silicon molecular bond of the compound. The process requires heating the vessel to break the bond of the silicon to transform it into a particular form, usually in small beaded shapes. Once the silicon enters this phase, they are ready to use for the next step.

Ingot and Wafer Production

The polysilicon is now used to turn them into wafers. To do this, the manufacturers will place the polysilicon into a container to liquidize them. The polysilicon will undergo several other processes in completing this production, such as the Czochralski and directional solidification.

In czochralski, the process involves growing a cylindrical ingot of the silicon by pressing a crystalline seed in the liquid form of polysilicon. Upon combining the materials, it requires slowly pulling upward to form into the required shape.

Then, after forming the silicon ingot, it will undergo directional solidification to cool it until it hardened and made it into a large silicon ingot. Finally, the hardened silicon ar thinly sliced into wafers. This is done by using special wire saws such as diamond-coated ones.

Cell Fabrication

After making the silicon wafers, they are now turned into PV cells through cell fabrication. This process will start with fixing the surface texture of the wafer by removing damages from sawing. The process also includes checking the capacity of wafers, which can be done in various ways depending on the device architecture.

Module Assembly

Finally, the last production process is the part where the components are assembled to complete the module. Usually, the fabricated cells are joined to busbars in the facility, which are then connected to glass sheets. Then, the cells are covered by another glass sheet for waterproofing.

Once the product is laminated, it is fitted with aluminum frames and a junction box to integrate the electrical cables. After everything is assembled, the PV panels are ready for testing and distribution once they pass the testing.

Where are the Majority of Solar Modules Manufactured?

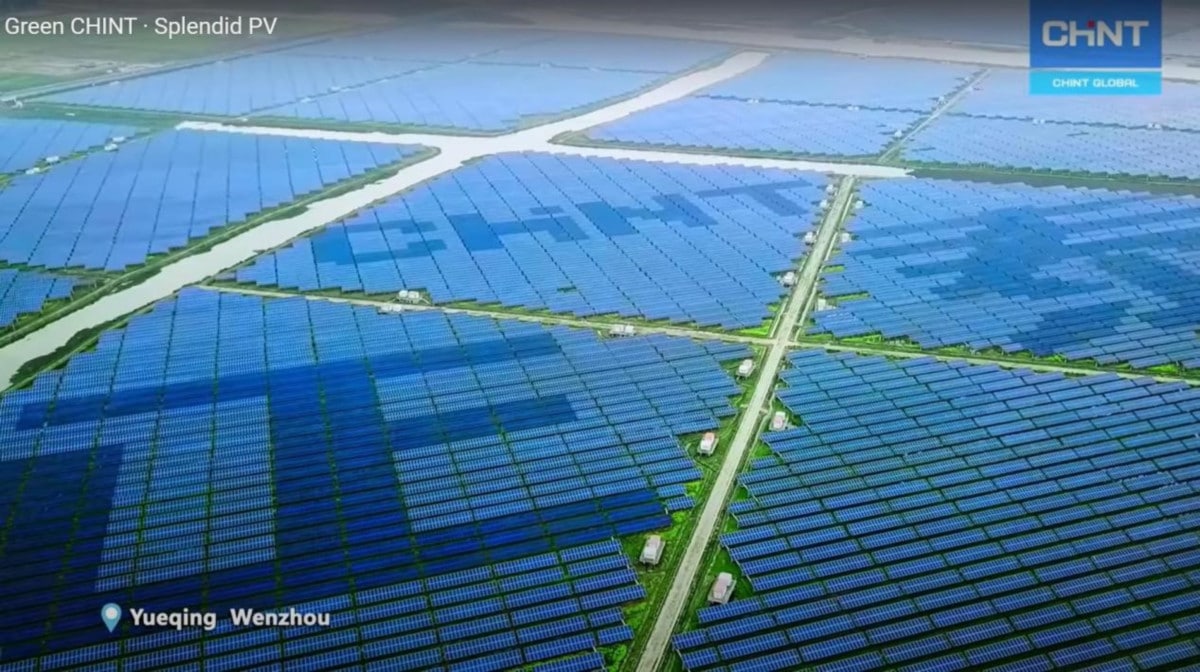

With the vast number of solar module manufacturers globally, it’s not easy to determine where these products are made. However, according to most surveys and data collected, China is the home of most solar panels manufacturers in the world. In fact, seven of the world’s top 10 module suppliers are located in China. While the rest of the distributors are from Canada, South Korea, and the U.S.

The National Energy Administration of China determines a total installation of 205.2 GW of PV in 2019, representing almost 27% of the overall installation globally. This data concludes that China is leading the market production of solar panels and solar energy systems market.

CHINT PV Products

Solar energy systems offer significant benefits to almost every industry, providing affordable electricity. But one sector that can take advantage of solar power is the manufacturing company. It will help them utilize the amount of energy without investing in expensive electric power supplies.

However, finding the best manufacturer of PV modules is an efficient way to get a reliable solar power system. CHINT is one of the pv module suppliers that you can trust with solid, authentic, and affordable products.

They also produce related products such as inverters, monitoring system products, and more. If you’re looking for a great place to buy solar panels and other solar energy components, CHINNT is the best option.

Conclusion

With the significant benefits that solar power can provide to households, businesses, and industries, it’s not surprising that there is a growing demand for solar power systems globally. So, PV module manufacturers are vital to the country for an affordable source.

However, it’s also essential for buyers to choose the right manufacturers to get the best solar energy system. The best way to ensure that the products will serve the purpose is to check the manufacturer’s legitimacy.

-metalclad-AC-enclosed-switchgear-banner.png)