Table of Contents |

Air Insulated Substations (AIS) play a pivotal role in the power system, ensuring the efficient and reliable transmission of electrical power from one point to another. These AIS substations are critical nodes in the power grid, facilitating the transformation and distribution of power to meet the ever-growing demands of urban and industrial areas.

Typical Components of AIS Substations

An AIS substation is a complex assembly of various components, each serving a specific function in the power management process.

1. Circuit Breakers

Circuit breakers are perhaps the most critical components within an AIS. They serve as the primary means of protection against electrical faults. When a fault occurs, the breaker interrupts the flow of electricity, thereby preventing damage to equipment and ensuring the safety of personnel. Modern circuit breakers are designed with high-speed operation and are capable of handling large fault currents, making them indispensable for reliable power system operation.

2. Disconnectors (Isolators)

Disconnectors, also known as isolators or switches, are used to safely disconnect parts of the electrical circuit for maintenance or in the event of a fault. Unlike circuit breakers, disconnectors are not designed to interrupt fault currents but rather to provide a visible break in the circuit, ensuring that no current flows through the disconnected section. This is crucial for the safety of maintenance personnel and for the integrity of the power system during outages.

3. Voltage and Current Transformers

Voltage transformers (VTs) step down high voltages to lower, safer levels for monitoring and control systems. Current transformers (CTs), on the other hand, are used to convert high currents to lower currents for metering and protective relaying purposes. Together, VTs and CTs enable the safe and accurate measurement of electrical quantities, which is vital for the operation of the substation and the power system as a whole.

4. Surge Arresters

Surge arresters protect the substation equipment from transient overvoltages, which can be caused by lightning strikes or switching operations. These devices are designed to divert the surge current to the ground, thereby preventing damage to insulation and other equipment. They are equipped with non-linear resistors that offer high resistance to normal operating currents but become highly conductive during a surge event. The use of advanced materials and designs ensures that surge arresters can handle the high-energy transients without themselves becoming a source of failure.

Each of these components is engineered to work in concert with the others to form a robust and efficient power management system. The design and selection of these components are guided by the specific requirements of the power system, including the voltage levels, the expected load, and the environmental conditions.

Applications of AIS Substations

Air Insulated Substations (AIS) are versatile and find extensive use in various aspects of power transmission and distribution systems. Their applications range from forming the backbone of transmission networks to serving as key components in urban distribution grids and industrial setups.

1. Transmission Networks

AIS substations are widely used in transmission networks, where they facilitate the transfer of electricity over long distances. They are particularly effective in areas with lower population densities, where the space for substation construction is more readily available. Their robust construction allows them to withstand various weather conditions, making them suitable for outdoor installations in a wide range of environments.

2. Urban Distribution Grids

In urban areas, where space is at a premium, the compact design of certain AIS configurations can be advantageous. They are used to step down voltages from high-voltage transmission lines to lower levels suitable for distribution to residential and commercial consumers. The ability to integrate AIS components into existing urban infrastructure without extensive civil works makes them a practical choice for many cities.

3. Industrial Applications

Industrial facilities often require reliable and high-capacity power supply solutions. AIS substations are used to provide the necessary power transformation and distribution within these settings. Their straightforward design and construction make them a cost-effective solution for industrial power needs.

4. Renewable Energy Integration

With the rise of renewable energy sources, such as wind and solar farms, AIS substations play a crucial role in integrating these sources into the power grid. They can be used to step up the voltage generated by these installations to match the grid’s requirements, ensuring efficient power transfer and distribution.

Advantages of AIS Substations

While the applications of AIS substations are diverse and widespread, it is their inherent advantages that truly set them apart in the field of power transmission and distribution.

1. Cost-Effectiveness

One of the primary advantages of AIS is its relatively lower cost compared to gas-insulated substations (GIS). The materials and construction methods used for AIS are generally less expensive. This cost difference can be significant, especially for large-scale installations.

2. Ease of Maintenance

The open design of AIS substations allows for easier access to components, simplifying maintenance and repair operations. Visual inspections can be conducted more readily, and replacement or repair of components can often be done without the need for specialized equipment or protective measures.

3. Reliability

Despite being exposed to the elements, AIS substations are designed to be highly reliable. They can operate effectively in a wide range of environmental conditions, including extreme temperatures, high humidity, and heavy rainfall. Properly designed AIS can also withstand natural disasters such as earthquakes and floods, ensuring continuous operation of the power system.

In short, AIS substations are a versatile and reliable solution for a variety of power system applications. Their cost-effectiveness, ease of maintenance, and adaptability make them a preferred choice for many utilities and industrial operators.

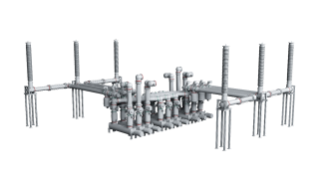

CHINT’s 126/145kV AIS Substation

CHINT’s 126/145kV AIS Substation is a testament to the innovation and advancement in the field of power transmission equipment. It is particularly beneficial for utility companies’ substations, booster stations in power generation projects, and step-down stations in large industrial projects.

Substation Components Highlight

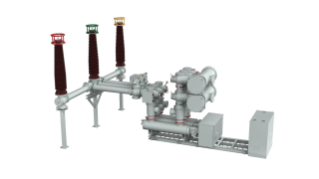

Circuit Breaker: With enhanced structural optimization and performance, CHINT’s circuit breakers ensure product longevity and stability, a critical factor for reliable power supply.

Disconnector: The use of integrated aluminum alloy for the conductive circuit improves durability and heat dissipation. The self-supporting finger design addresses common issues such as overheating and sticking, while the fully enclosed structure protects against external environmental impacts.

Surge Arrester: CHINT utilizes leading resistor materials to enhance the current-carrying capacity of its surge arresters. Safety features like the explosion-proof film and pressure relief valve prevent accidents, and a decoupler ensures disconnection from the system in case of grounding faults.

Voltage and Current Transformer: CHINT’s transformers are optimized with digital pulse welding technology and aluminum alloy casting, addressing issues like oil leakage and corrosion. The KEMA certification guarantees that their products meet international quality and performance standards.

What’s more, CHINT provides a delivery cycle that is shorter than the industry average, ensuring that substations can be readied for operation within 35 days after blueprint confirmation, meeting the urgent demands of projects.

Conclusion

In conclusion, AIS substations are a fundamental component of modern electrical power systems, offering a blend of reliability, versatility, and cost-effectiveness. With applications spanning from transmission networks to urban grids and industrial complexes, AIS substations, such as CHINT’s 126/145kV AIS Substation, exemplify the convergence of innovation and practicality. Their ease of maintenance, robust design, and adherence to international standards make them a preferred solution for utilities and industries worldwide.

If you have any questions or need further assistance, don't hesitate to reach out to us.

-metalclad-AC-enclosed-switchgear-banner.png)