A high-performing facility entails a continuous power supply and minimal outage risks. But to meet these needs, the facility must invest in an Air Circuit Breaker that safeguards equipment and personnel from a high inflow of electricity.

Yet, picking the right ACB involves many considerations. Failure to specify these factors can lead to power failure, equipment damage, or even worse, electric shock or injuries to personnel.

Here, we discuss the essential considerations when selecting an ACB to help data centers and power distribution sites make an informed choice.

What is the Role of Air Circuit Breakers in Critical Facilities?

An Air Circuit Breaker uses pressurized air to extinguish the arc that forms when the circuit’s contacts separate due to excessive current flow or a short circuit. The arc can interrupt electric flow or damage the equipment, so the ACB’s pressurized air quickly dissipates the arc’s heat via specialized nozzles.

As ACBs direct an arc away, safe and stable current flow is maintained. This makes ACBs essential in critical facilities that regularly operate using high energy.

For instance, data centers consume substantial energy for the uptime of storage systems, servers, and transmission networks. When this equipment goes online simultaneously, demand for electric current increases, which also elevates the risk of a short circuit or overcurrent. Once the current flow exceeds the “safe” threshold, the ACB can step in. It can instantly “disconnect” the affected circuit and keep the system’s infrastructure working.

ACBs are also helpful in manufacturing plants that use heavy equipment. During a power malfunction or interruption, the ACB can protect the machines and avoid costly repairs or replacement. Public infrastructure, such as airports and railway stations, also relies on ACBs to maintain a consistent electric supply and support safe, reliable transport operations.

Key Considerations for Selecting an Air Circuit Breaker

If your facility needs an ACB, it is important to consider these factors to ensure that the device is safe and reliable.

Monitoring & Smart Integration

Real time data is essential for tracking key ACB parameters such as breaker status, load currents, and trip frequencies. This is especially important in data centres and process industries where system interruptions can lead to significant operational risks.

A common approach is to connect the ACB with a BMS (Building Management System) or SCADA (Supervisory Control and Data Acquisition) platform. These industrial software systems help monitor complex infrastructure, reduce the need for on-site inspections, and support continuous operation.

Modern ACBs also support predictive maintenance by analysing usage patterns and component conditions to identify early signs of potential failure. This function is valuable for preventing downtime, improving safety, and extending the service life of electrical equipment.

When choosing an ACB, consider for models that offer smooth integration with BMS or SCADA and support predictive maintenance to enhance monitoring, reliability, and efficiency.

Fault Interruption Capacity

Fault interruption capacity (FIC), also known as breaking capacity, is the maximum current that the ACB can safely interrupt in case of a short circuit. To avoid an ACB failure, the device’s fault interruption rating must match the facility’s maximum short-circuit current (Icu).

To do this, check your system’s transformer size, source impedance, and conductor lengths. This will help you estimate the system’s breaking capacity. Then, select an ACB with Icu that is equal to or above the estimated FIC.

Environmental and Installation Flexibility

The ACB must be highly resilient against dynamic environmental conditions. For example, in data centre applications, it may need to operate at temperatures as high as 50 °C without derating. Hence, check if an ACB has a premium design and material that can withstand your facility’s ambient temperature.

Some ACBs also need strong ingress protection (IP) ratings or a dust-proof enclosure, especially if the facility has a corrosive or dusty environment (e.g., chemical plants or manufacturing factories).

Compliance and Certification

If an ACB is compliant or certified, this means that a competent regulatory organization (local or international) recognizes that it is safe, reliable, and high-performing. Moreover, an ACB that is certified comes with formal documentation that proves how it satisfies rigorous quality tests.

Here are some key standards and certification bodies for ACBs:

- IEC 60947-2: an international blueprint for the design, construction, and performance of low-voltage circuit breakers.

- UL (Underwriter Labs): An accredited standards developer in the US and Canada for electrical products and technologies.

Introducing CHINT’s NA8 Air Circuit Breaker

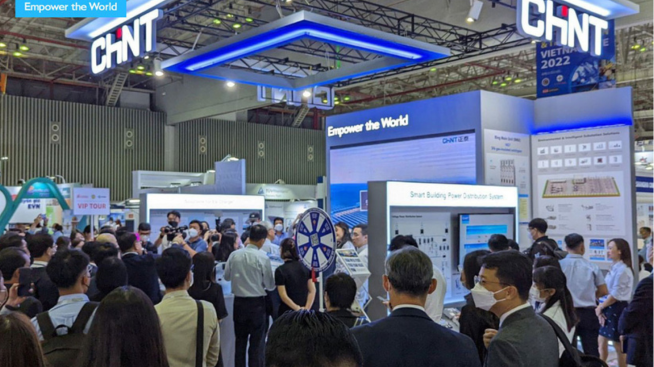

A great deal of ACBs are available nowadays in the market, but only a few meet the key considerations we discussed above. CHINT's NA8 ACB is a leading world-class ACB solution designed for stable, safe, and highly efficient operation.

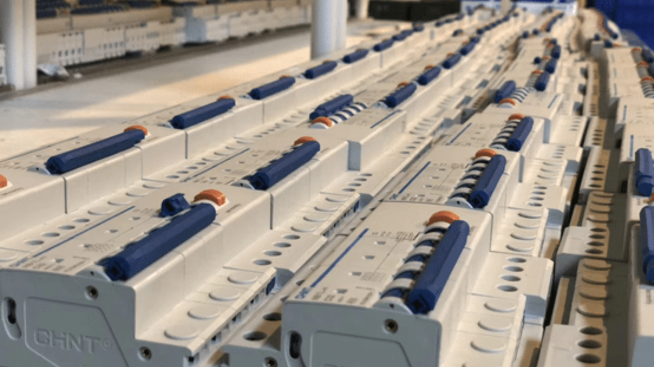

NA8 Air Circuit Breaker is a draw-out type/fixed type ACB that supports horizontal connection, vertical connection, and mixed connection. Its electrical and mechanical properties are designed to support a wide range of temperature conditions and resist electromagnetic interference.

Technical Data:

- Frame Sizes range from 1600A up to 7500A

- Breaking capacities Available: N, H, and HU

- Rated voltages range from 380/400/415 up to 800/1000/1150V

- Comes with 3 or 4 pole configurations

- Applicable for ambient temperature -5℃~+40℃ (certified), and also peripheral ambient temperature -45℃~+70℃ (M type ), -20℃~+70℃ (H type )

Key Features

- Supports ERMS (Energy Reduction Maintenance Settings): Minimises the time between fault detection and tripping, reducing the risk of injury during maintenance.

- Supports SOE (Sequence of Events): Captures and restores waveform data during a fault, making it easier to review and diagnose the root cause.

- Equipped with NFC (Near Field Communication) technology: Allows electricians to monitor system status onsite quickly and efficiently.

- Compatible with SPTU (Smart Portable Test Unit): Enables verification of L, S, I, and G protection settings to ensure compliance with electrical design requirements.

Explore a High-Performing, Reliable, and Safe Air Circuit Breaker From CHINT

Safety is paramount when a facility runs equipment using high electrical current. For this reason, it is vital to invest in a top-quality ACB that can secure the current flow if a short circuit or overcurrent occurs.

CHINT is a globally-renowned smart energy solution provider that focuses on energy systems of supply, storage, transmission, distribution, and consumption. At the heart of our business is the commitment to promote clean energy, energy distribution, big data, and energy value-added services. We offer leading-edge air circuit breakers compliant with industrial standards and designed to support the daily operations of data centers and critical power distribution sites. Ensure your equipment’s longevity and personnel’s safety with our sophisticated ACB products.