Table of Contents |

Arc Fault Detection Devices (AFDDs) are electronic components that detect when an arc or short circuit forms across a wire, and quickly and automatically shuts off power by interrupting the electric current. There is always a risk of one short-circuiting to another.

These hazards often occur with household appliances like microwaves, coffee machines, ovens, hair dryers, or stoves, or industrial machines like welding equipment, electric saws, and heaters for boilers or turbines.

In other words, AFDDs detect the fault condition and protectively interrupt the circuit before it can cause harm to people nearby, as well as save on costly equipment damages.

What Causes Arc Fault

Arc faults are caused by electromagnetic interference, arc osculation, and also the collision between two different currents in the same circuit. It can also occur when an electrical machine is not properly grounded, and thus it is susceptible to external disturbances.

It is critical to detect arc faults as this may prevent future problems from occurring—such as fire hazards and damage to electrical wiring systems from sparking—which would otherwise cost lots of money to repair or replace.

AFDDs sound an alarm when there is a problem so that maintenance can be done before worse things happen. Examples of arc fault scenarios include overloaded outlets, when they are plugged into too many appliances at one time, damaged circuit breakers or fuses, and arcing between two wires that come into contact with each other.

How Does Arc Fault Occur

There are two common types of arc faults: series arcing faults and parallel arcing faults.

Series arc fault emanates from an arc that lies between two parts of the same conductor. For instance, when a connection is improperly tightened, or a conductor is damaged, a localized hot spot happens and ultimately carbonizes insulating materials within the conductor.

Since carbon is a conductive element, it allows excessive current flow at different points. Carbon is then deposited non-homogeneously, and the currents passing through it generate arc for path facilitation.

In contrast, parallel arc fault occurs between two varied conductors. This can happen due to a bad connection or deteriorating insulation. An arcing fault causes significant temperature rises, which may lead to fires.

Ideally, when insulating materials between two conductors become damaged, a lot of current is created between them. However, such current is too weak for the circuit breaker to consider a short circuit, and the residual current protective devices cannot detect it since it is not transmitted to the earth.

When these leakage currents pass through the insulating materials, they optimize their paths by generating arcs that slowly change the insulating materials to carbon. One of the standard features of the parallel arc faults is the ignition of fire.

You can prevent or minimize an arc fault by not allowing liquids (not even water) to come into contact with your electrical system and avoid using damaged, frayed, or crushed cords. You should also try to keep the wires in your home separated and bundled together so that they are less likely to cross each other and touch an exposed part of the wire (which can cause them to short-circuit).

How Does Arc Fault Detection Work

Arc fault protection devices work by sensing the arc in a circuit and stopping it from progressing. They use microprocessors to identify the voltage curves and current flow, which indicate a fault and will automatically trip the affected circuit.

There is a lot of potential for damage when an arc occurs from conductor to conductor, especially because electricity will travel the path of least resistance. A failure in the system can lead to electricity leaking out and into any other object it is touching, which could create a shock hazard or start a fire.

For an arc fault protection device to work, it needs some way of sensing the current flow through a circuit and must be able to stop that current once it senses that there is an arc occurring somewhere along its path.

There are different types of devices that attempt to accomplish this. Some sense current flow through the entire circuit, and others will sense only the path where an arc is occurring and only get triggered when that arc reaches its limit. Once a device has been triggered, it will either stop the current flow or turn off a circuit to avoid any potential damage.

Related Article: AFDD Fundamentals and Advantages

Related Article: How Arc Fault Circuit Breakers Protect Your Family and Property

Related Article: Why Arc Fault Detection Device (AFDD) Can Minimize Electrical Fire

How to Install Arc Fault Detection Devices

There are two major types of AFDDs: solid-state and electromechanical.

Solid-state AFDDs are composed of solid-state components such as silicon diodes (SiDs) and thermistors. This type of device is advantageous because the components used in its assembly do not require any maintenance or repair since these components will not be easily defective or broken.

On the other hand, electromechanical AFDDs are composed of electromechanical components, such as relays and bimetallic switches. They are more secure than solid-state devices because their associated components will be fail-safe to ensure its proper function. However, the highly sensitive mechanism that it has is prone to damage.

The installation requirements of both types of AFDDs are similar and straightforward. A qualified electrician should perform the installation procedure to prevent accidents that may occur during or after installation.

To install an arc fault detection device, you first need to identify the point of installation, as it needs to match the problem at hand. The point of installation should be within a distance that will center around the damaged part.

After finding out where to install the device, you need to figure out what kind of electrical problem it is. Then you can decide if an arc fault detection device will work for that problem. To do this, you measure and analyze the line voltage, current on load, neutral current, phase angle, and line impedance at each load end. By using the measured data, you can determine if an arc fault detection device is applicable for your application.

AFDDs should be installed at the home’s highest point, on the first floor, or outside. However, one can install AFDDs as far from entryways and exits as possible – this is where smoke will evacuate during a power outage.

Most importantly, you should ensure your electric tool are unplugged from any power source before working on or near an AED. Notably, the device is placed between the hot and neutral terminals on a three-wire circuit and detects when current passes through it in either direction by conducting or arcing.

In the event of a power failure, it is best to ensure that all electric tools and appliances are unplugged and all extension cords are pulled away from the walls and items they might be plugged into; if this is not possible, at least unplug the circuit breaker at the main electrical panel until it can be safely reconnected.

Conclusion

While many people believe electricity safety depends on the quality of your outlet strip and power cord, this is not entirely true. AFDDs are designed to detect shorts or breaks in the electrical circuit, giving you the protection you need in case an unexpected event is happening. Additionally, these devices will prevent accidental knockouts by alerting you when there is a danger of an arc taking place.

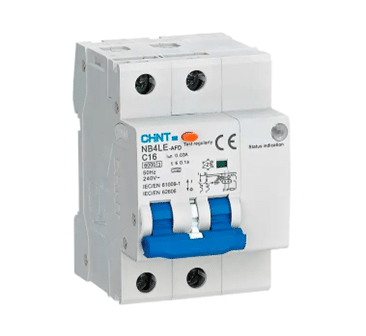

Fortunately, Chint Global has industry-leading Arc Fault Detection Devices that offer the latest in protection against lightning strikes and power surges. With our surge arresters and other parts on hand, any damage caused by an electrical shock will be repaired fast and hopefully well before your fuses get overloaded. Therefore, the next time the power goes out and your appliances fail to work, contact us at Chint Global and learn how our products make life much more convenient for homeowners and businesses.

-metalclad-AC-enclosed-switchgear-banner.png)