Table of Contents |

A project acceptance report is often required during project acceptance to adequately test air circuit breakers before approval. However, directly applying high fault currents poses risks like damage or shortening the ACB’s lifespan. This created a testing paradox for maintaining reliable protection without endangering equipment under evaluation. Industry sought a solution allowing full diagnostic assessments for certification while mitigating product concerns. CHINT’s new Smart Handheld Test Unit provides such a solution through advanced simulation, faithfully recreating faults offline. Now, authorized personnel have a portable test unit to streamline acceptance testing and validations safely, without compromising ACB durability long-term.

CHINT Smart Handheld Test Unit: Comprehensive Overview

The CHINT Smart Handheld Test Unit offers a comprehensive solution for testing ACBs. With a series of high-quality features and functions, it allows for efficient and reliable protection testing. Its key characteristics include:

1. Strong Compatibility

The handheld test unit is compatible with all series of CHINT ACBs. As the leading manufacturer of air circuit breakers, we have various product lines to meet different needs. Our smart handheld test unit can test the full range of our models easily. Field workers don’t need to learn the usage methods of different test units, hence saving time and improving efficiency. They can focus on testing and maintenance rather than spending efforts adapting to separate devices.

2. User-friendly Design

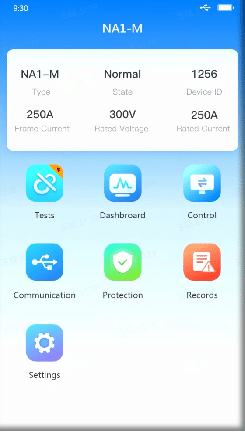

The 4.6-inch, 720*1280 HD capacitive touchscreen of the handheld test unit operates like a smartphone intuitively. With a high-resolution display, all readouts are easily visible. High sensitivity ensures operation while wearing gloves. Thick protective gloves are commonly used for safety around live circuits, but the touchscreen can still be accurately operated.

Commonly used buttons of the smart test unit allow operation while gloved with no issues. An external protective non-slip cover prevents slipping or damage from drops. It protects against impacts if accidentally dropped on site.

3. Easy Operation

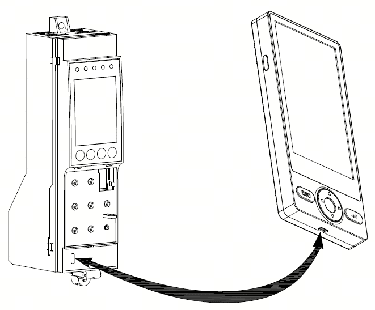

An Ethernet port connects the test unit conveniently versus screws. Screw-based connections can be time-consuming when switching between multiple breakers for testing. Technicians must spend precious minutes attaching cables one at a time. However, our Ethernet solution connects in seconds to each ACB quickly.

Wiring multiple ACBs is much faster with our portable handheld test unit. It greatly reduces the time spent per unit. Technicians can evaluate more equipment daily, hence improving productivity and servicing more customer needs efficiently.

4. Battery Design

The lithium battery of the electrical test unit charges like a smartphone, with the charging port being the same as that of a smartphone. Two hours of charging provides up to two hours of active use before it needs recharging. It provides technicians with sufficient battery life for thorough on-site testing and validation.

5. Support Manual and Automatic Test

Testing is more efficient and accurate without affecting circuit breaker life. Automatic analysis and comparison of results reduces maintenance costs and misoperation. The industry and customers have fully recognized this. Detailed automatic record-keeping gives clients comprehensive reports for each protected system. Personnel save time with automated analysis that ensures consistent, reliable results.

The Test Process

The test process using the CHINT Smart Handheld Test Unit is straightforward to follow. Here are the steps involved in the test process:

Input Test Value of Fault Current: On the touchscreen interface, simply select the anticipated fault current value level.

Press ‘Start’: Once the current level is set, press the ‘Start’ button to initiate the diagnostic testing sequence.

Press ‘Save’: Upon test completion, pressing the ‘Save’ icon stores the results report from that test run for future reference.

Press ‘Export’: The handheld test unit allows you to access past reports through the records section. All history test results can be found under “Test Records”. You can use the ‘Export’ function to transfer data to the SD card as a backup or for record-keeping purposes.

Overall, the testing workflow has been optimized for maximum efficiency while still providing the detailed output monitoring needed for performance validation and maintenance documentation.

Conclusion

At CHINT, our Smart Handheld Test Unit provides a reliable solution for testing ACB protection functions without risk of damage. Its strong compatibility, user-friendly design, easy operation, long battery life, and support for manual or automatic testing allow for efficient and accurate protection testing. As a global leading provider of smart energy solutions, our reliable products improve energy efficiency and support green development.

-metalclad-AC-enclosed-switchgear-banner.png)