Introduction

Starting an electric motor pulls 5-7 times more current compared to normal operation called inrush current. This stresses electrical systems and trips protection devices that are not selected correctly. Compressors, pumps, conveyors, chillers, and other inductive loads, must handle high inrush, that’s why its motor protection is important through choosing the right control components.

Why High-Inrush Loads Change the Rules of Motor Protection

High-inrush currents change how motor protection devices should be selected. During motor startup, while inrush can be short, it is still so intense that it can stress breakers, contacts, and relays if components are not built for it. In this scenario, the system thinks something’s wrong, but there actually isn’t. Therefore, trips can occur, and this happens because components were selected for steady-state current and not transient, which should be the case. The Molded Case Circuit Breakers (MCCBs), contractors, and overload relays respond differently to these two different currents and when these are not coordinated, the system can react prematurely since the components were not designed for the unexpected current.

This behavior can be likened to transformers charging. The high current appears briefly before it settles down. Understanding this is important because this will help you choose a heavy duty control component which allows motors to start smoothly while protecting the system from faults.

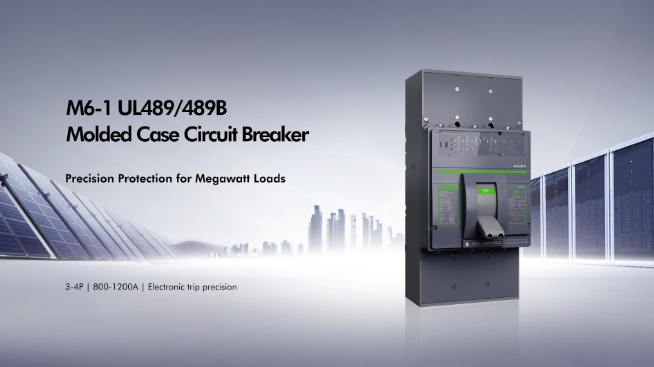

Role of MCCBs in Heavy-Duty Control

In high-inrush loads, MCCB is the first protective layer which determines whether a motor can start smoothly, or be stopped by nuisance trips. In this case, MCCBs not only protect against faults, but they also tolerate normal startup currents.

When motors have high inrush, adjustable long-delay and short-delay settings are important. These give the motor sufficient time to accelerate without the breaker tripping too early. Also, short-delay settings must be fine tuned. If set too low, the breaker will react to normal inrush current as if it is a fault.

Breaking capacity and operational voltage ratings also influence system safety in industrial environments. MCCBs safely interrupt high fault currents, operating reliably at system voltage levels.

Understanding your motor’s starting current is important when finding the best MCCB settings for motor protection. There are MCCBs that are under-sized or over-sensitive, which can contribute to tripping or inconsistent motor behavior. CHINT’s MCCB lineup offers multiple frame sizes and adjustable protections, allowing engineers to fine-tune performance and reduce the occurrence of nuisance trippings during startup. These products are built with precision and strict quality control, ensuring it meets international standards in safety and reliability across industrial, residential, and commercial industries.

Choosing Contactors for Heavy-Duty Industrial Loads

Contactors are electromechanical switches that turn motors on and off and during high inrush loads, it becomes mechanically and electrically stressed especially during startup. When a motor energizes, the contactor must close against current surges beyond normal levels. If the contactor is not designed for this, contacts may overheat or wear out quickly.

The making and breaking capacity is important when it comes to contactors. It must safely close and open circuits, and carry high transient current. Another factor to consider is the coil stability. An unstable coil may cause chatter leading to accelerated wear, especially when voltage dips occur.

For heavy-duty industrial loads, contact materials and design are crucial. Contactors that are heavy-duty use robust alloys and contact shapes that can withstand inrush loads and reduce erosion. Inductive loads such as HVAC compressors, industrial fans, and pumps require specific contactors that are specifically made for motor duty.

Industrial contactors offered by CHINT are suitable options, as these are designed to handle demanding operating conditions in commercial and industrial settings. When choosing contactors, make sure to assess if these can handle heavy-duty loads and if they are safe, reliable, and efficient when it comes to distribution and control.

Overload Relay Selection for Motor Applications

Overload relays are different from MCCBs when it comes to motor protection. MCCBs are designed to tolerate high in-rush on startup, while overload relay protects the motor during long-term overcurrent that can damage the motor or slowly overheat it.

Selecting an overload has different factors to be considered. One is thermal accuracy, which ensures that the relay must trip depending on how the motor heats up and not because of its current levels. Also, time-current characteristics matter because short overloads are acceptable but not sustained overloads.

Adjustable full-load current (FLA) settings allow relay to march the nameplate rating, and trip class selection ensures relay responds appropriately mashed on the type and starting behavior of the motor, as some motors have longer startup time before protection activates.

Another factor is environmental conditions. High ambient temperature may affect how quickly a relay trips. In some instances, derating is required.

Overload relays act as an intelligence layer, protecting motor insulation and mechanical wear and they must work smoothly with contactors and MCCBs. CHINT’s roster of overload relays are ideal choices for small and large motor protection needs, with its wide adjustment range, manual and automatic reset modes, and suitability for industrial automation which help extend motor lifespan.

How to Reduce Nuisance Tripping in Motor-Start Circuits

Nuisance tripping normally occurs during motor startup, but it doesn’t necessarily mean there’s a problem. It helps to identify the difference between true faults versus inrush-related peaks. The former usually causes sustained or repeated trips, whereas inrush-related peaks are expected and short.

Issues arise mostly because of poor coordination between MCCBs, overload relays, and contactors. If these are not matched correctly, one of them may trip too early and cause the other devices to malfunction. For example, an MCCB with overly sensitive settings may trip before the motor reaches its intended speed.

Another one that causes impact is the startup method, which influences inrush behavior. Direct-on-line (DOL) creates the highest inrush load, while star-delta starters reduce inrush through lowering of starting voltage. Meanwhile, soft starters smoothly control current and torque. These methods determine how motor protection devices are to be set.

Practical decision checks help in identifying the cause too:

- If the breaker trips instantly on startup but not on normal running, you have to check the instantaneous settings.

- If overload relays trip after repeated starts, thermal buildup across cycles may be the problem.

Understanding these load behaviors and motor startup response will help reduce nuisance trips.

Coordination of MCCBs, Contactors, and Overload

Good motor protection happens when all motor protection components work together. MCCBs, contactors, and overload relay all have specific tasks and having poor coordination between these three is the common cause of motor startup issues.

This is why coordination curves are important. These show how each device responds as current increases over time. In high inrush loads, MCCB must tolerate short startup surges without tripping, all while still protecting the cables and equipment from real faults happening. If the breaker reacts quickly, the motor may not be able to start.

The contactor is in the middle of the system which should handle repeated high-current switching without damage. The breaker must always clear serious faults before the contactor is stressed beyond its capacity.

Lastly, overload relays are in charge of long-term protection. It must be able to trip before the motor overheats or damages the insulation, but not during normal startup or quick load changes.

Systems with MCCB’s adjustable trip settings, contactors with switching endurance, and properly matched overload relays demonstrate how coordinated selection reduces nuisance trips and extends equipment life. CHINT’s CJX2 AC contractor, for example, can be combined with proper thermal relay to protect circuits, while its overload relays are ideal for industrial automation and control systems. CHINT’s motor product lineups are well-coordinated, ensuring dependable motor protection across all units.

Applying the Framework: Control Component Selection for High-Inrush Loads

This section should act as a synthesis. Write a checklist-style structure that mirrors competitor selection methodologies (e.g., staged decision processes in power supply selection articles). Include:

Define the inrush magnitude based on motor characteristics.

Select MCCB frame, breaking capacity, and trip curve to accommodate that inrush.

Select a contactor capable of making/breaking heavy inductive loads repeatedly.

Select an overload relay with thermal protection matched to operational cycles.

Confirm coordination across the three devices under worst-case startup conditions.

Now that you understand how inrush loads affect motors, choosing the right components is easier. Here’s a checklist on how you can avoid nuisance trips and ensure reliable motor operation:

1. Define the inrush current.

Begin by knowing how much current the motor draws at startup. Factors like motor type, size, and starting methods, all affect the levels of inrush, so this information sets the foundation for everything that follows.

2. Select the MCCB.

The MCCB that you choose must have a frame size and breaking capacity that is suitable for the system’s fault level. The trip curve must enable short-duration inrush current without tripping, while still protecting the cables and equipment in real faults.

3. Choose the contactor.

Get one that is rated for heavy inductive loads. This must be able to close and open circuits in high inrush conditions without excessive wear or damage repeatedly.

4. Pick an overload relay.

Get one that is able to match the motor’s full-load current and thermal behavior. This overload relay must protect against long-term overheating and remain stable on normal startup cycles.

5. Check the coordination under worst-case scenarios.

Lastly and most importantly, you have to confirm that the MCCBs, contactor, and overload relay work well together on startup conditions. The breaker must tolerate the inrush, the contactor must switch reliably, and the overload relay must be inactive until true overload conditions happen.

By following this structured approach, you can be sure that your motor control systems will work safely, reliable, and dependably.

Where Intelligent Control Adds Value in Industrial Facilities

Besides basic protection devices, modern industrial facilities need intelligent control too to keep systems more efficient and stable. Intelligent monitoring, automation, and system-wide coordination help add another layer of reliability. By tracking loads and coordinating how equipment responds during normal operation and startup, you can fine-tune your protection settings and help understand how systems work through intelligent solutions. Through these features, you can avoid unnecessary shutdowns and help reduce stress in your motor and even electrical components too.

CHINT also offers intelligent electrical solutions products, which help support more stable operations. Its reactive compensation technologies like the JKF8 controller show how modern components support reliable operations, especially in facilities with motors starting and stopping all day. It’s designed for precise control in low-voltage distribution systems. It helps improve the power factor and reduce energy loss, while increasing optimum efficiency in your power systems.

Conclusion

Control component selection for high-inrush loads are crucial for a reliable motor system. When the components are properly coordinated, issues like nuisance trips can be reduced, and your equipment life can be extended. As a global provider of motor solutions, CHINT products are ideal for your industrial and electrical needs.

.png)

.png)