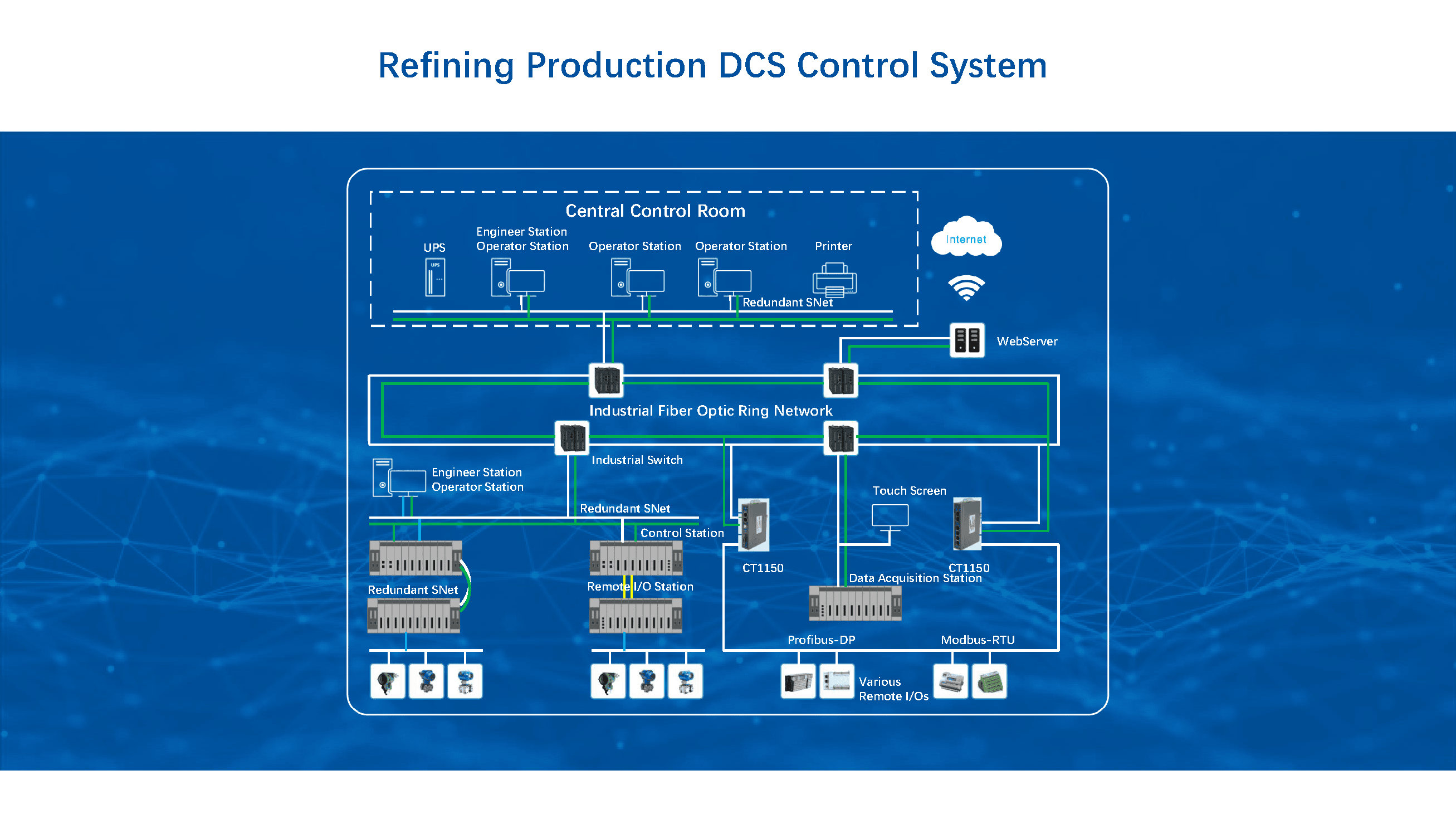

Automation and integrated control systems optimize workflows, boosting production efficiency while reducing downtime.

The system ensures stable, safe operations throughout the entire production process, minimizing risks and improving system uptime.

The solution reduces project costs by an average of 9%, providing a cost-effective approach to electrical control and automation.

With an average reduction of 12% in project duration, our solution accelerates project timelines, enabling quicker operational deployment.

By optimizing production processes, this solution supports the sustainable development of enterprises through efficient and environmentally friendly practices.

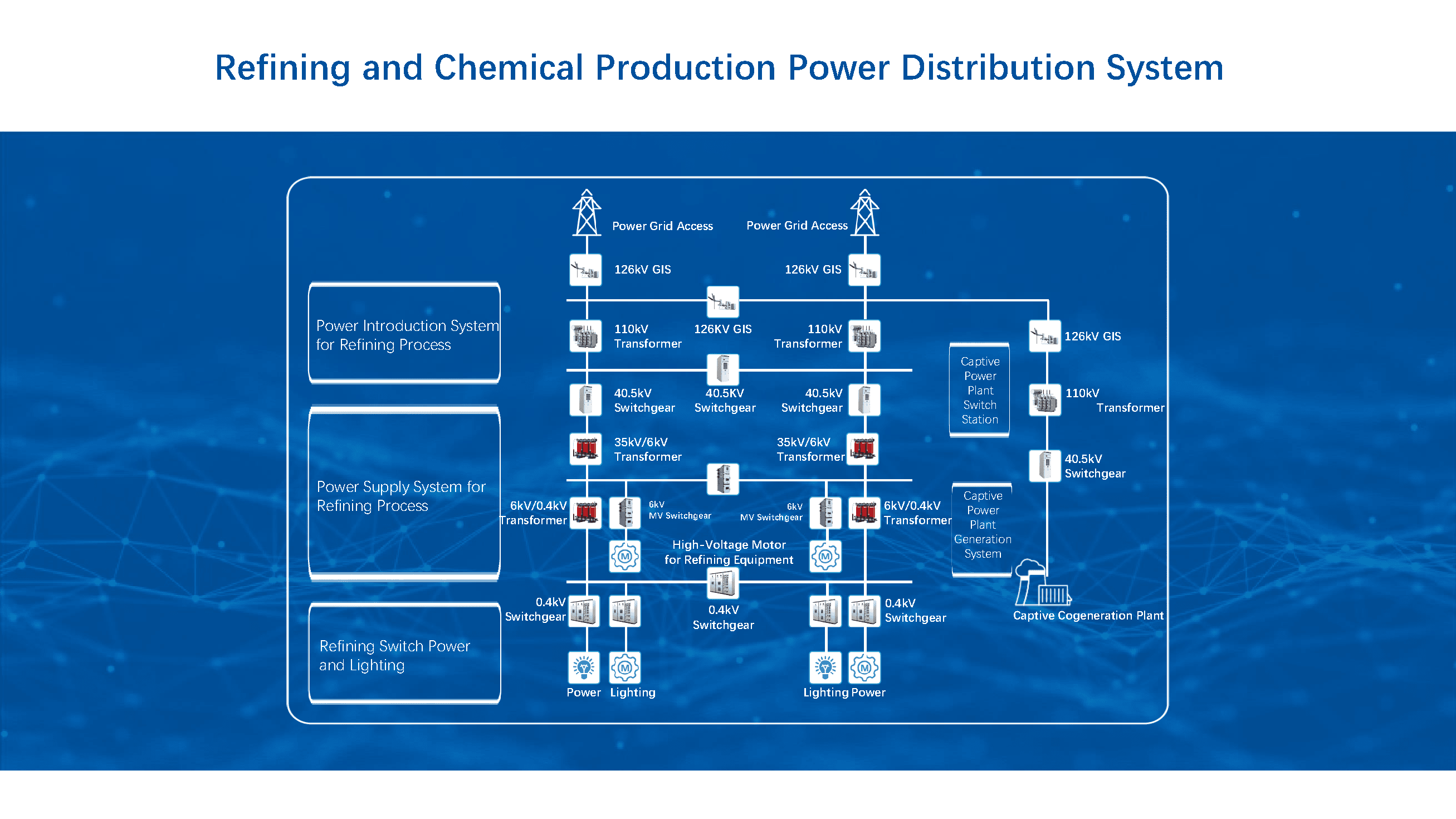

Ideal for use in oil extraction sites and refining operations, where stability, safety, and automation are critical for efficient and secure processes.

Suited for petrochemical plants, where integrated control and instrumentation systems help manage complex processes efficiently.

Ensures reliable electrical control and safety during the transportation of petrochemical products, supporting smooth and safe operations.

Perfect for large-scale energy infrastructure projects in the petroleum sector, where cost-effective, efficient, and sustainable systems are essential.

CHINT offers a complete solution that integrates electrical control, automation, and safety systems, tailored to meet the unique needs of the petroleum and petrochemical industries.

With years of experience, CHINT provides reliable, high-quality solutions specifically designed for the demanding conditions of oil extraction and refining operations.

From design to execution, CHINT’s solutions ensure smoother project management, delivering high-quality results with reduced complexity.

The system reduces both project duration and costs, offering an optimal balance between performance and investment.

Our solutions are engineered with a focus on long-term operational stability, helping businesses reduce environmental impact while maximizing production efficiency.