Overload relays are crucial protection devices. They protect motors from excessive current. It’s valuable because excessive current could cause overheating and damage. In this article, we’ll explore trip curves, a vital aspect of overload relay operation that determines when and how they respond to overload conditions.

Trip Curve: Overview

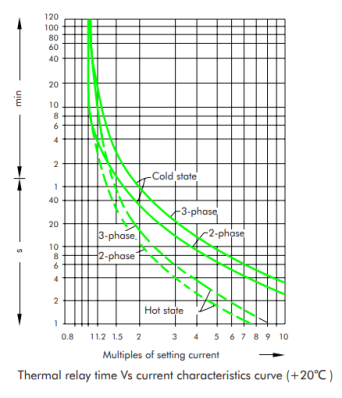

A trip curve is a graphical representation of an overload relay’s response time. It shows how quickly the relay will trip based on the amount of current flowing through it. The horizontal axis displays current as a multiple of the relay’s setting. The vertical axis shows the tripping time in seconds. Trip curves help engineers select the right bimetallic overload relay protection for specific motor applications. They ensure motors receive adequate protection without unnecessary downtime.

Trip curves typically use logarithmic scales for better visualization. It makes reading across a wide range of values easier. The curve’s shape reflects the thermal characteristics of the motor it protects. Different motors have different heat tolerance levels. The right trip curve matches these specific thermal limitations.

NXR Series Thermal Overload Relays Trip characteristics

Trip Class for Overload Relay Explained

Trip class defines how quickly an overload relay responds to severe overloads. It indicates the maximum time a relay takes to trip when carrying six times its rated current. Common trip classes include 10, 20, and 30. A Class 10 relay trips within 10 seconds at 600% current. Class 20 trips within 20 seconds. Class 30 takes up to 30 seconds.

Different applications require different trip classes. Quick-start applications often need faster-acting Class 10 relays. Heavy-duty applications may require slower Class 20 or 30 relays. The selection impacts both motor protection and operational continuity. Proper trip class choice prevents costly downtime and equipment damage.

Cold State vs Hot State Trip Curve: Characteristics and Differences

Overload relays exhibit different trip curves depending on their thermal state. A cold-state trip curve applies when the relay starts from the ambient temperature. A hot-state trip curve applies when the relay has been operating and is already warm.

The key difference is the response time. Cold-state relays take longer to trip because they must first heat up. Hot-state relays respond faster since they’re already near their tripping temperature. This matters in applications with frequent starts and stops. Motors that cycle frequently operate more often with hot-state characteristics. In industrial processes, understanding these differences is crucial for proper motor sizing and protection coordination.

System designers must account for both states when selecting proper protection. Temperature memory features in modern relays help address these differences. They track thermal conditions across operational cycles.

Two-Phase vs Three-Phase Trip Curve

Trip curves also vary between two-phase and three-phase electrical systems. Two-phase trip curves apply when current flows through only two phases. Three-phase curves apply when current flows through all three phases of a balanced system.

The differences are significant for protection strategies. The two-phase operation typically triggers faster tripping times. This is because phase loss creates unbalanced conditions that are more harmful to motors. Three-phase balanced loads distribute heat more evenly. They allow slightly longer operation during mild overloads. Thermal overload relay systems must account for both scenarios.

Some relays automatically adjust their response based on how many phases experience the overload condition. The phase imbalance detection prevents motor damage from single-phasing conditions.

Conclusion

Understanding trip curves is key to effective motor protection, as different trip classes determine response times to severe overloads. It's also important to distinguish between cold and hot state curves, and to recognize how two-phase and three-phase operations impact tripping behavior.

At CHINT, we offer the reliable NXR Thermal Overload Relay series. Our relays provide overload and phase loss protection for AC motors with frequencies of 50/60 Hz. They work with voltages up to 690V and currents from 0.1 to 630A. We have designed them with temperature compensation, action indication, and multiple reset options. They can be plugged into contactors or installed independently for maximum flexibility. Visit our website to explore our protection solutions.